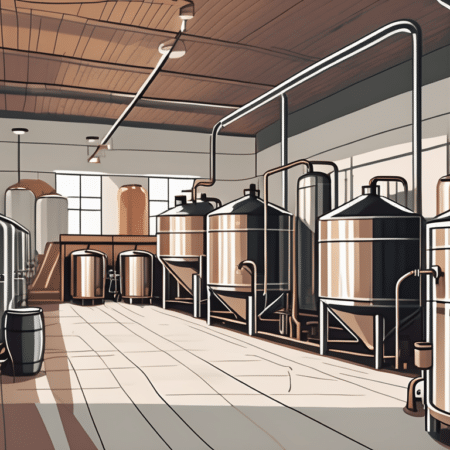

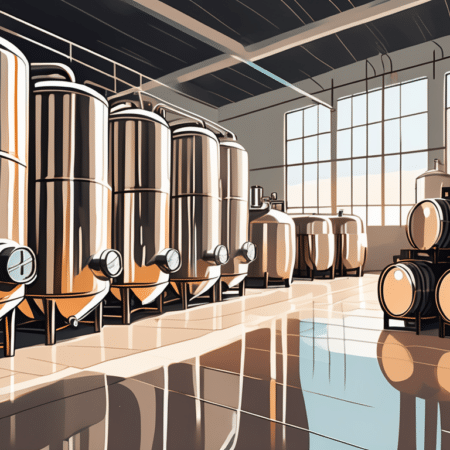

So you’ve decided to get an epoxy flooring for your brewery. Now all you need to do is apply the epoxy flooring properly. While this is a simple task, there are several things that need to be done to guarantee your floor comes out just the way you envisioned it.

Before Applying Epoxy

The absolute first step before applying your epoxy coating, is to prep your floor. It is essential that you clean your floor thoroughly. If you’re working on a concrete base, fill in any cracks or patch areas that need care before you start to clean. Once the damages, if any, have been repaired, it’s time to clean. Be sure to catch any areas you might overlook while preparing your epoxy coat. Oil spots will need to be removed and the floor will need to be degreased. Your floor is cleaned properly and you will want to make sure you vacuum thoroughly to rid of any remaining dust and debris.

Methods

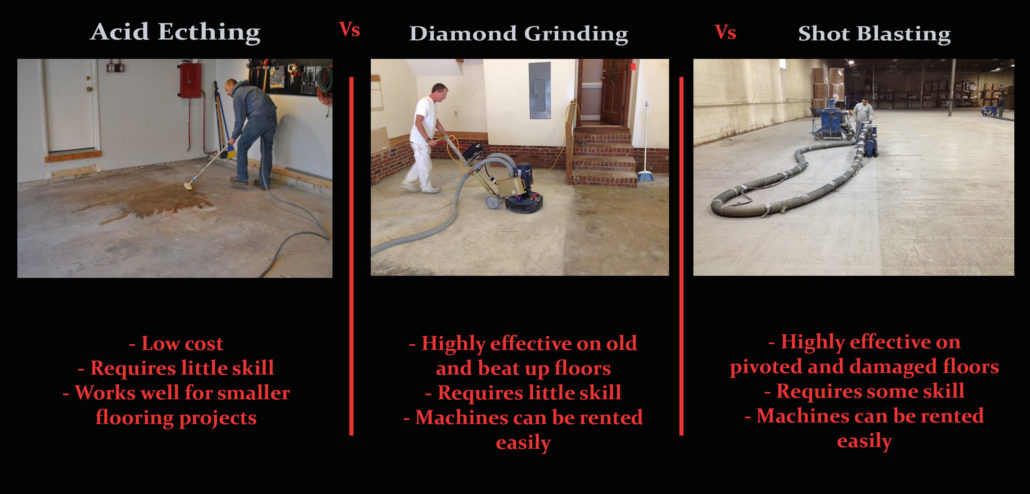

There are three main methods for preparing your floor for epoxy work, so take your pick on which one will best suit your needs.

1. Acid Etching

The first is acid etching. This technique is the most D.I.Y. option, as other techniques require machinery or skill. And is best used for concrete bases. First you need to apply the acid solution to your floor. Once it is spread out evenly use a scrubber, a stiff bristle broom, or a similar tool to work the acid solution. Once that it’s done, let the acid sit for up to 10 minutes, this will allow the process to take effect. Next you have to remove the spent acid. This can be done through power washing and then vacuuming once the floor has dried. Make sure to remove the residue before the acid dries. Finally you’ll need to neutralize any remaining acid residue. Using a diluted solution of simple green will work well on most floors (approximately 4oz per gallon of water)

2. Diamond Grinding

The second method for preparing your floor is diamond grinding. This method will restore smoothness to your floor, which is needed prior to an epoxy coating. The diamond grinding method requires the use of machinery, however, it is quite easy to do. You will need a floor grinder with the proper attachments for your floor. Once the machine is turned on, use a side-by-side swaying motion to smooth out the entire surface of your floor. After this is complete, vacuum heavily to clear away any residue left behind. Be sure to always keep the grinder in motion to avoid grinding circular rings and low spots into the floor.

3. Shot Blasting

The final method that can be used to prepare your floor is shot blasting. There are various styles for this technique but all require machinery to flatten out a surface. Some people prefer diamond grinding to this method, but both will get the job done. The machine will pelt tiny metallic beads into the floor to blast away any stains or damages to the base. The advantage of this, as opposed to diamond grinding and acid etching, is that there will most likely not be any residue left over, as the machine captures everything. This technique requires a some skill and should be used on larger scale jobs.

Floor preparation is the most important aspect to achieving a smooth and even outcome. Be sure to research your method of choice before and as always the Brew Floors Team is here to answer any questions you have!

After all of this is complete, you will be ready to apply your epoxy flooring!

58 thoughts on “How To Prep Your Floor For An Epoxy Coating”

Hi,

I want to epoxy our man cave. It’s covered in old glue that is scraping off very quickly. Do recommend acid washing this to remove the glue and filling gaps before applying the paint.

Thanks

Hello,

We would reccomend use a mastic glue remover, then mechanical prepartion via diamond gridning or sand blasting. Acid washing may work however the mastic left behind from the glue will not bond well with a new coating. It needs to be fully removed.

Cheers,

The Brew Floors Team

Any epoxy prepping suggestions for a concrete area that a power washer could not be used?

Hi Melanie,

I would suggest mechanical prepartion via diamond grinding or sand blasting. This is going to be the best form of prep to profile the floor.

Cheers,

The Brew Floors Team

Hi

I have a garage floor that has been diamond ground back but have noticed it bit in to the floor in places. It’s not deep but rough, It’s only in a few spots. Will an epoxy paint cover this?

Hi Kevin,

A thick coat of epoxy (or multiple coats) should cover the floor but if a very aggresive diamond plate was used (<40 grit) and multiple passes it's possible that you might still see the profile of the floor even after a coat of epoxy. I would recommend using a high build epoxy system and laying it on a bit thicker if you are worried. Feel free to send some pictures over to info@brewfloors.com and we can make a better assessment.

Cheers,

The Brew Floors Team

I have a 2 car garage that I want to apply epoxy to the floor. I had several cracks that I used a 2 part epoxy repair kit to repair. The garage has a cheep epoxy paint on it. If I use a diamond cutter buffer, do I need to remove the epoxy repairs I made or just grind them like the paint ?

Thank you

Hi Bill,

We would suggest prepping the entire floor, removing the existing paint and then recoating with a new product. If the crack repair has held up you do not need to remove it but yes you should still prep it because it will be receiving a new coating. The new coating needs a good profiled substrate in order to bond properly.

Cheers!

The Brew Floors Team

Nice! In epoxy coating, use a product made for preparing concrete floors to etch or acid wash the floor.

We have a floor that has a concrete-based overlay typically used around swimming pools. It is very rough. It was sealed with an solvent based acrylic sealer and remains porous. Can an epoxy go directly over this? Thanks!

Hi Julie,

I would not go directly over the surface without prepping the floor. Depending on the product you are using will also determine the prep needed to ensure proper adhesion of the coating. I would recommend sanding or diamond grinding the sealer off and the proceeding with the product you select for the floor. If you simply throw material down over the acrylic sealer you run the risk of the product not bonding, especially if they are from different manufacturers.

Cheers,

The Brew Floors Team

I have a new floor that was burnished and sealed with some kind of waterproof costing. I just finished prepping with a floor grinder there is about an inch around the perimeter that the tool couldn’t reach. Is this acceptable? Also, is there anything special in need to do around the floor drain? Thanks!

Hi Ian,

I would hit those areas with a small grinder or sanding pad just to be safe. It’s possible that those areas could be problematic if not prepped properly.

Cheers,

The Brew Floor Team

I have a very dirty oily garage floor that sweats most of the time either now spring or humid days , would you just acid etch it or diamond grind it . Do it need to be bone dry before coating it . Thanks

Hi Nathan,

We would suggest diamond grinding if there are oil stains on the floor. Have you performed a moisture test on the floor? If not I would suggest doing so to see if you will need to apply a moisture vapor barrier primer. Yes the floor should be completely dry and dirt free before application begins. Do not apply over dirt and/or a floor with moisture present.

Cheers,

The Brew Floors Team

Hi Guys,

I have a question about the metallic epoxy floors in the condo. Do any of you have idea if there is any soundproof underlayment I can use on concrete floors to meet City requirements? Or what kind of material I can use and can be painted with epoxy . I really, really liked epoxy floors and need to find solutions for this. Thank you for any suggestions!

I have a new slab that we broom finished. What do l need to do to prep for paint.

Hi Mike,

New concrete needs to wait 28 days to fully cure and dry. After the waiting period we would suggest either using an acid etch and power wash OR mechanically prepping the floor via diamond gridning. Mechanical prep is the best way to prep the floor and open up the pores for coating adhesion however on new slabs you will be okay just using an acid etch. Please note though that if you do not mechanically prep the floor the broom finish of the concrete will show through the coating so if you do not want this type of look in a final coating then you will need to mechanically prep the floor.

Feel free to send us an email and we can suggest one of our products that would be a good fit for you project.

Cheers,

The Brew Floors Team

Hi! I have new slab in my living area that I’d like to seal. What would you recommend for best results, grinding or blasting?

Hi Frank,

We would recommend diamond grinding to start. You really only need to shot blast if you are looking to heavily profile the concrete for a thick coating or if there was a super thick coating that currently exists. You want to achieve a CSP(concrete surface profile) or min 2 but ideally a 3 in order for most epoxies to adhere properly. Feel free to send us an email with more info and we can help point you in the right direction in terms of product.

Cheers,

Kevin

I’m in a different scenario than most folks. I have a house that was built in 1976. The basement floor is concrete and was painted. The paint is peeling off extremely easily. My concern is the concrete itself. It’s not like typical concrete. It’s hard to explain but it’s almost like it’s sandy and impossible to stop it from coming apart. I can vacuum it and sweep it and it seems like it’s constantly having fine sediment coming off. What can I do to prep the concrete for a epoxy coating? Would you recommend I use a concrete leveling product to put over the concrete prior to applying the epoxy coating?

Hi John,

From what you describe it seems like the concrete is failing and either needs to be replaced or like you mention a self leveling product should be used. If you apply a coating over your current substrate it will most likely not adhere properly if the concrete is brittle and falling apart.

Feel free to send us some photos and we can help point you int he right direction in terms of product suggestions.

Cheers,

Kevin

I’m epoxying a brand new basement floor. What # grit would you consider less aggressive. Also what do I use to fill floor joints and the cracks between the floor and poured walls?

Hi Brian,

You can use a grit above #60. This will be a bit more fine while still providing the non slip resistance you want. Depending on joint size and length you could you a crack filler. See our crack repair epoxy product here. It goes down similar to spackle and dries as hard as concrete. It’s very easy to work with. If you have wider joints then I would suggest using an epoxy crack filler with a foam backer rod (dependent on size). If you were looking to create more of a cove from the floor to the wall then using an cove mortar product like this will work well or you can use a product called easy cove and coat right over it.

Cheers!

The Brew Floors Team

I have a 20+ year old floor. You can probably imagine what that looks like. Oil spots, etc. I’m handy so using machinery properly is not a concern. What would be the best way to prep this floor, with an etch, diamond grind, or a combo of the 2?

Hi JC,

We would recommend either diamond grinding or shot blasting or a combination of both. If you have oil stains the only way to truly remove these stains and open up the floor for a high performance application is mechanical prep. Acid etch will not suffice. Feel free to send us over some pictures and we would be happy to assist.

Cheers,

The Brew Floor Team

What preparation is needed for a new concrete floor to be able to apply two part epoxy

The floor will need to be prepped via acid etching, diamond grinding, of shot blasting. Please refer to this article for more info all all three prep methods.

Prep Your Floor

Cheers,

The Brew Floors Team

i have a floor that is concrete stained but terribly damaged at this point I’m looking at epoxy floor. can i put epoxy over it and how would I prep it?

Hi Sal,

We would suggest mechanically prepping the floor via diamond grinding or shot blasting. If you just put epoxy over a damaged and stained floor the coating at first will adhere but will fail down the road. The prep is the most important thing when it comes to installing an epoxy coating.

i have a new floor power floated with a hardener. can i still apply epoxy? how do i prepare the surface

Hi Samuel,

Yes but you will need to prep the floor via mechanical prep. Either shot blasting or diamond grinding.

The Brew Floors Team

I am building an aircraft hangar and want to epoxy the floor. Should I have the contractor seal the floor when pouring?

The area to be coated is 4,800 ft2 can I start with acid washing? If not, what are my steps before applying.

Thank You

WBC

William,

I would not recommend that the contractor seal the floor. You will have to “unseal” it before any coating should be applied. Acid etching is effective however mechanical grinding or shot-blasting is the preferred method for floor prep. The idea behind prepping the floor is to give it enough “grip” for the coating to adhere properly. Acid etching does not really accomplish this but rather removes dirt, debris, and residue stuck on the floor.

The Brew Floors Team.

Hi, for a new construction home whose garage floor is very new, what method of prep do you recommend?

For Diamond grinding, can i use just an angle hand grinder? This is a 3 car garage.

Hello Nami,

We would recommend diamond grinding for new concrete. You can use less aggressive diamond pads. I would think it would be very difficult to hand grind an entire 3 car garage floor so your best bet it to locate your nearest equipment rental store, (Aramsco, Sunbelt, Home Depot) and ask what type of diamond grinding machines they rent.

Cheers,

The Brew Floors Team

Hi can you fill gaps or hollows in the concrete with the apoxy

Hi Mary,

Yes you certainly can but most epoxies intended use is not for this. you are better off using a crack filler or patch kit rather than an epoxy to fill in gaps, holes, and dings in the floor.

Cheers,

The Brew Floors Team

Hello, If your concrete has never been sealed or coated with anything. Do you still have to diamond grind the concrete or can you just acid etch the surface?

Yes, even if your concrete has never been sealed or coated it still needs to achieve a CSP (concrete surface profile) that is adequate for the coating you are going to apply. If you do not prep, you run the risk of having your floor fail. Concrete floor preparation is the MOST important step in any epoxy application.

My contractor will grind and vacuum. Then he wants to damp mop (not very wet). Is this a good idea before applying epoxy to concrete?

Hi Jack,

Yes that is fine! I would recommend though to use denatured alcohol in lieu of water to mop the floor after its grinded and vacuumed. This will help to clean the floor of any fine and residual dust and dirt and will flash off (dry) very quickly. Water can take a bit longer to full dry and you do not want the floor to have any water on it before coating.

Cheers,

The Brew Floors Team

I’ve never used shot blasting but I’m seriously considering it to save a little time on each job.

Shotblasting is not for the faint hearted but it will do a great job prepping any concrete floor.

It is good to know you should have a super clean floor before applying an epoxy floor. My wife and I aren’t the cleanest of people, but we do want to put in an epoxy floor in our garage. We’ll have to do some deep cleaning before we hire someone to do the flooring.

Hi Oliver,

Yes – the prep is the most important part of any epoxy installation. If you have a clean and well prepped floor the better result your final floor will yield.

Cheers!

please what are the names of the chemicals that are used to install 3D epoxy floor and is there any location in Nigeria where the product can be purchased?

There is a good video showing how to apply 3D epoxies here.

Hello Brew Floors Team-

We’ve been doing different types of coatings for years but recently were contacted to bid a brewery. Since this happened we have been looking closer into different epoxy flooring solutions. Do you have a specific type of diamond grinder that you like the best or do you acid etch everything? Thanks for the tip, youre blog is useful.

Cheers-

Hi Jared,

Depending on the current state of the substrate we recommend different types of prep. A general rule of thumb though is if there is an existing coating on the floor then prep via diamond grinding using a 40-50 grit diamond head. This will be sufficient enough to remove the existing coating without tearing down the concrete. Every floor is different but we are glad to give you a more precise recommendation if you want to send us a direct email at info@brewfloors.com.

Cheers!

The Brew Floors Team

Alex,

Thanks that’s what I figured. We’ve done that grit diamond before. Is there a special type of epoxy system you recommend for breweries. Quartz epoxy? I might follow up with an email.

Hi Jared,

Yes all of the Brew Floors Coating systems were made for breweries. Each brewery is different so their is not a “best” system but if you are looking for the strongest most durable coating system then either a quartz or mortar type floor would be the best. We actually sell both and have seen alot of success with these. Usually a quartz and mortar floor are a bit more expensive though so a great and cost efficient alternative is our Brew Floors III system which is a two layer novolac epoxy coating.

Feel free to send an email and I can answer any specific questions you may have.

Cheers!

Alex

The Brew Floors Team.

We have been thinking of an Epoxy Floor for awhile now. This article was very informative. We had no idea as to the amount of prep needed for the Epoxy Floor. And your article is much easier to read than the side of the container. The last thing we would want is our new Epoxy Floor to start peeling up. I want to make sure that we understand the floor prepping instructions really well. Especially since it’s something we will have to do in house. We really want this to happen, and it looks like we should have a great opportunity this spring to get our new Epoxy Floor. We just can’t afford all of the cost to have it professionally done. Maybe if we can save some money on the prepping it would be extremely helpful. We have found that dish soap cleans the grease spots up without too much effort. I wasn’t aware of checking for the moisture content though. If we happen to find too much humidity in my concrete, What would be a good sealer to insure a good bond on our floor? After we get the floor really clean and seal it up if necessary, we will be looking into the acid etching most likely. What acid do you use to etch the floors? And is it readily available without having to order it? Thank you so much for the information. It was really helpful.

Hi Randall,

Thanks for the note! I’ve sent you an email with more information on the moisture barrier product. A good Acid etch is one called Acid Magic. You can find this at your local hardware store.

– The Brew Floors Team

Can you send me the moisture barrier product you recommend?

Hi Andrea,

See our moisture vapor coating here.

Cheers,

The Brew Floors Team

Great post, I’m looking to prep my garage floor, I’ve Just looked up acid magic but it says one of it’s advantages is it doesn’t etch concrete… Isn’t that what we need it to do?

Hi Catherine,

I am not sure where you found this information but Acid Magic is a great replacement for muriatic acid for prepping a concrete substrate before coating. We have been proponents of Acid Magic for years and have never seen issues with customers using this as a prep method.

Cheers,

The Brew Floors Team