Brewery floor coatings play a crucial role in maintaining a safe and efficient brewing environment. As a brewery owner or operator, it is important to understand the importance of these coatings and how they contribute to the overall functionality and longevity of your brewery. In this comprehensive guide, we will explore the various aspects of brewery floor coatings, including their role in breweries, the importance of quality, different types available, the application process, and maintenance and care tips to keep your coated floors in optimal condition.

Understanding the Importance of Brewery Floor Coatings

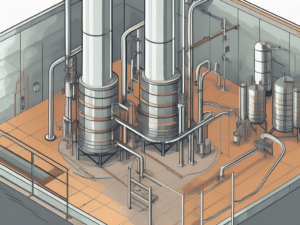

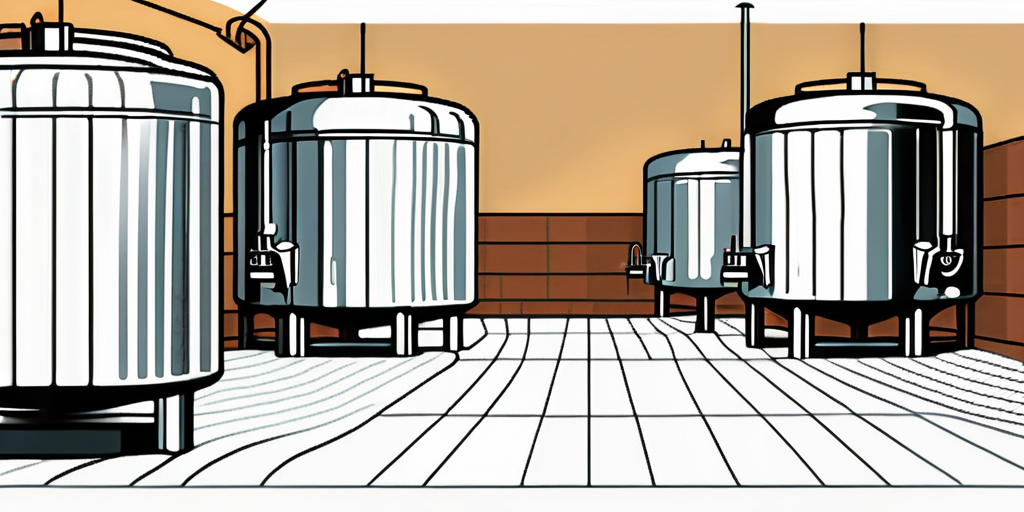

Brewery floor coatings are specifically designed to withstand the unique challenges that breweries face on a daily basis. Unlike regular concrete floors, brewery floors are exposed to a variety of harsh substances, including hot liquids, chemicals, and heavy equipment. Without proper protection, these factors can cause significant damage to the floors, leading to safety hazards and costly repairs.

When it comes to brewery operations, every aspect of the facility plays a crucial role in ensuring the quality and safety of the final product. From the brewing process to the packaging and distribution, every step must be carefully executed. One often overlooked aspect is the brewery floor. While it may seem like a simple surface, the floor is subjected to constant abuse and must be able to withstand the demanding conditions of a brewery environment.

The Role of Floor Coatings in Breweries

In breweries, floor coatings serve multiple purposes. Firstly, they provide a protective barrier between the concrete floor and potential threats such as chemicals and spills. This helps to prevent the floor from absorbing these substances, making clean-up easier and reducing the risk of bacterial growth.

Imagine a bustling brewery, with employees moving swiftly to complete their tasks. In this fast-paced environment, spills are bound to happen. Whether it’s a small splash of beer or a chemical spill, the floor coating acts as a shield, preventing these substances from seeping into the concrete. This not only makes the clean-up process more efficient but also ensures that the floor remains hygienic, reducing the risk of contamination.

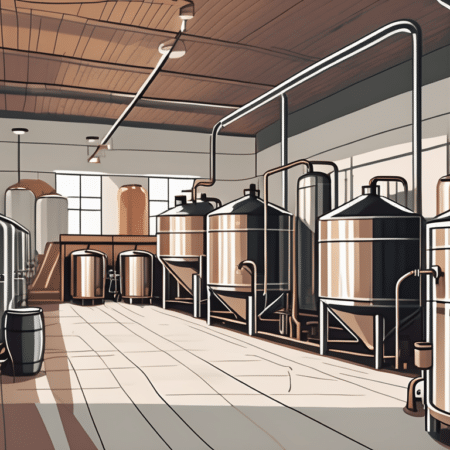

Secondly, floor coatings enhance the overall safety of the brewery by providing slip resistance, improving traction for employees, and reducing the chances of accidents or injuries. The brewery floor is a high-traffic area, with employees constantly on the move, carrying heavy equipment and kegs. Without proper traction, the risk of slips and falls increases significantly. By applying a quality floor coating, breweries can create a safer working environment for their employees, minimizing the risk of injuries and the associated costs.

Additionally, floor coatings can improve the appearance of the brewery, creating a more professional and aesthetically pleasing environment for both employees and customers. A well-maintained and visually appealing brewery not only boosts employee morale but also leaves a lasting impression on visitors. With the right floor coating, breweries can achieve a clean and polished look, elevating the overall ambiance of the facility.

Why Quality Matters in Brewery Floor Coatings

When it comes to brewery floor coatings, quality is of utmost importance. Investing in high-quality coatings ensures that your floors will be able to withstand the demanding conditions of a brewery. Inferior coatings may quickly deteriorate, leading to costly repairs and potential shutdowns of operations.

Imagine the consequences of a floor coating that fails to meet the rigorous demands of a brewery. Not only would the floor be vulnerable to damage from hot liquids and chemicals, but it could also pose a safety risk to employees. A deteriorating floor coating could create uneven surfaces, increasing the chances of trips and falls. Moreover, the potential for bacterial growth due to inadequate protection could compromise the quality and safety of the beer being produced.

By choosing top-quality coatings, you can have peace of mind knowing that your brewery floors are well-protected and will stand the test of time. These coatings are specifically formulated to withstand the unique challenges of a brewery environment, ensuring the longevity and durability of the floor. With a high-quality floor coating, breweries can focus on what they do best – crafting exceptional beers – without worrying about the integrity of their floors.

Different Types of Brewery Floor Coatings

When it comes to brewery floor coatings, there are several options available, each with its own unique advantages and characteristics. It is important to carefully assess your specific brewery needs and select the coating that best suits your requirements. Let’s take a closer look at three common types of brewery floor coatings:

Epoxy Resin Coatings

Epoxy resin coatings are a popular choice for brewery floors, and for good reason. These coatings are known for their exceptional durability and chemical resistance. They create a seamless and smooth surface that is not only aesthetically pleasing but also easy to clean and maintain. This is particularly important in a brewery setting where spills and messes are common. Epoxy resin coatings can withstand heavy foot and vehicle traffic, making them ideal for areas such as brewing rooms, bottling lines, and storage areas. With an epoxy resin coating, you can rest assured that your brewery floor will be able to handle the demands of a busy production environment.

Polyurethane Coatings

If you’re looking for a brewery floor coating that offers excellent chemical resistance and the ability to resist staining, polyurethane coatings are a great option. These coatings are highly resistant to abrasions, impacts, and scratches, making them suitable for areas where heavy equipment or machinery is used. In a brewery, where kegs and barrels may be moved around, having a floor coating that can withstand such activity is crucial. Additionally, polyurethane coatings offer UV stability, which means they will not yellow or degrade when exposed to sunlight. This is particularly important if your brewery has windows or skylights that allow natural light to enter the space.

Acrylic Coatings

For those looking for a cost-effective solution for their brewery floors, acrylic coatings are worth considering. These coatings provide good resistance against chemicals and stains, making them a practical choice for a brewery environment. They are also relatively easy to apply, which can save time and money during the installation process. Acrylic coatings are typically used in areas with light to moderate foot traffic, making them suitable for taprooms, tasting rooms, and administrative areas. While they may not be as durable as epoxy resin or polyurethane coatings, they still offer a reliable and budget-friendly option for brewery floors.

When selecting a brewery floor coating, it is important to consider factors such as durability, chemical resistance, ease of maintenance, and cost. By choosing the right coating for your brewery, you can ensure that your floors not only look great but also withstand the demands of a busy production environment.

The Process of Applying Brewery Floor Coatings

Properly applying brewery floor coatings is essential to ensure optimal performance and longevity. This process involves several steps, including:

Preparing the Brewery Floor

Prior to applying the coating, the brewery floor must be thoroughly cleaned to remove any dirt, grease, or existing coatings. This can be done using industrial-grade cleaners or floor degreasers. It is important to repair any cracks or imperfections in the concrete before proceeding with the coating application.

Applying the Coating

Once the floor is cleaned and repaired, the coating can be applied. This is typically done using specialized equipment such as rollers, brushes, or sprayers, depending on the type of coating being used. Multiple coats may be required to achieve the desired thickness and durability.

Drying and Curing Time

After the coating is applied, it is important to allow sufficient drying and curing time. This ensures that the coating fully bonds with the concrete floor and reaches its maximum strength and resistance. The drying and curing time can vary depending on factors such as temperature, humidity, and the type of coating used. It’s crucial to follow the manufacturer’s instructions for the specific product being used.

Maintenance and Care for Coated Brewery Floors

Maintaining and caring for your coated brewery floors is crucial to ensure their long-term performance and durability. By following these maintenance tips, you can extend the life of your floors:

Cleaning Techniques for Coated Floors

Regular cleaning is essential to keep your coated brewery floors in optimal condition. It is important to use mild, non-abrasive cleaners and avoid harsh chemicals that can damage the coating. Sweeping or vacuuming the floor regularly will help remove dirt and debris, preventing it from scratching or wearing down the coating. If spills or stains occur, they should be promptly cleaned using a mild detergent or cleaner recommended by the coating manufacturer.

Regular Maintenance Tips

Performing routine maintenance tasks can help prevent major issues and prolong the life of your coated floors. This may include checking for any signs of wear or damage, such as cracks or chips, and repairing them promptly. It is also important to monitor the condition of the coating and reapply a topcoat if necessary, according to the manufacturer’s recommendations.

Dealing with Wear and Tear

Over time, brewery floors may experience wear and tear due to heavy use. It is important to address any issues such as delamination, chips, or scratches as soon as they arise. This may involve spot repairs or recoating the affected areas to maintain the integrity of the entire floor.

In conclusion, brewery floor coatings are essential for maintaining a safe, functional, and aesthetically pleasing brewing environment. Understanding the role and importance of these coatings, as well as selecting the right type for your specific brewery needs, is crucial. By following the proper application process and implementing regular maintenance and care, you can ensure that your coated brewery floors withstand the unique challenges of the brewing industry for years to come.