In any brewery, the flooring plays a crucial role in ensuring a safe and efficient operation. From withstanding heavy equipment to handling spills and maintaining hygiene standards, brewery flooring requires careful consideration and proper maintenance. In this guide, we will explore the importance of brewery flooring, discuss the different types available, delve into the installation process, and provide tips for maintaining your brewery floor for years to come.

Understanding the Importance of Brewery Flooring

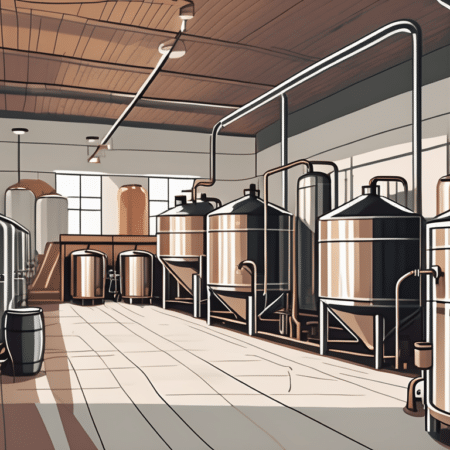

When it comes to breweries, the role of flooring goes beyond mere aesthetics. The right flooring system can prevent accidents, minimize downtime, and contribute to the overall cleanliness of the facility. A well-maintained brewery floor also increases the lifespan of equipment and reduces unnecessary repair costs.

The Role of Flooring in a Brewery

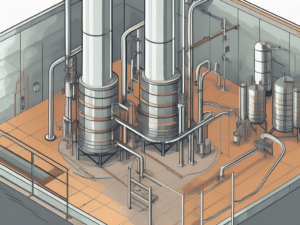

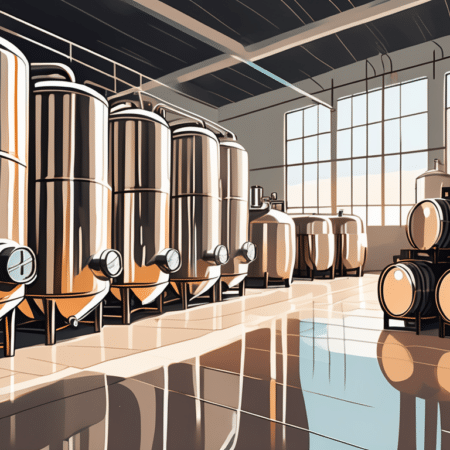

Brewery flooring acts as a foundation for the entire operation. It must withstand heavy loads, constant foot traffic, and exposure to various substances such as chemicals, heat, and moisture. A durable flooring system supports these demands and ensures a safe working environment.

One of the key roles of brewery flooring is to provide a level and stable surface for the movement of heavy equipment and materials. Breweries often have large tanks, kegs, and other machinery that require frequent movement. Without a sturdy and reliable floor, the risk of accidents and injuries increases significantly.

Furthermore, brewery floors are exposed to a variety of chemicals used in the brewing process. These chemicals can be corrosive and cause damage to ordinary flooring materials. A specialized brewery floor is designed to resist chemical attacks, ensuring longevity and reducing the need for frequent repairs or replacements.

In addition to withstanding heavy loads and chemical exposure, brewery flooring must also be able to handle extreme temperatures. Brewing involves the use of hot water, steam, and boiling liquids, which can cause ordinary flooring materials to warp or crack. A high-quality brewery floor is engineered to withstand these temperature fluctuations, ensuring the safety of the workers and the integrity of the facility.

Key Factors to Consider in Brewery Flooring

Before selecting a floor for your brewery, several important factors should be evaluated. The flooring should be resistant to chemicals, abrasions, and impact. It should also be easy to clean and maintain, and provide a non-slip surface to prevent accidents. Additionally, temperature and moisture control must be taken into account to prevent damaged equipment and product spoilage.

Chemical resistance is crucial in brewery flooring as it comes into contact with various substances like cleaning agents, acids, and alkalis. A chemically resistant floor prevents these substances from seeping into the concrete or causing damage to the floor surface, ensuring a hygienic environment for brewing operations.

Abrasion and impact resistance are equally important factors to consider. Brewery floors are subjected to heavy foot traffic, the movement of equipment, and the occasional accidental drop of heavy objects. A durable floor that can withstand these impacts will minimize the risk of cracks, chips, and other forms of damage that can compromise the safety and functionality of the brewery.

Another critical aspect of brewery flooring is ease of cleaning and maintenance. Breweries require regular cleaning to maintain hygiene standards and prevent the growth of bacteria or mold. A flooring system that is easy to clean and maintain saves time and effort, allowing the brewery staff to focus on their core tasks.

Furthermore, a non-slip surface is essential in a brewery to prevent accidents caused by wet or slippery floors. Spills are inevitable in a brewing environment, and a non-slip floor provides traction and reduces the risk of slips, trips, and falls.

Lastly, temperature and moisture control are vital considerations in brewery flooring. Breweries often have areas with high humidity levels, and the flooring must be able to handle these conditions without deteriorating. Moisture-resistant flooring prevents the growth of mold and mildew, which can affect the quality of the beer and pose health risks.

In conclusion, brewery flooring plays a crucial role in ensuring the safety, efficiency, and longevity of a brewery. By considering factors such as chemical resistance, abrasion and impact resistance, ease of cleaning, non-slip surfaces, and temperature and moisture control, brewery owners can select the right flooring system that meets their specific needs and contributes to the success of their operation.

Different Types of Brewery Flooring

When it comes to choosing the right flooring for breweries, there are several options available, each with its own unique advantages and considerations. Factors such as budget, specific brewery needs, and anticipated foot traffic play a crucial role in determining the most suitable flooring option.

One popular choice among breweries is epoxy resin flooring. This type of flooring is highly durable and offers excellent chemical resistance. Its seamless installation creates a strong bond with the concrete substrate, resulting in a surface that can withstand heavy equipment and frequent cleaning. Breweries often opt for epoxy resin flooring due to its impermeability, making it resistant to spills and moisture.

Polyurethane concrete flooring is another viable option for breweries. This type of flooring offers exceptional resistance to chemicals, thermal shock, and impact. It is particularly suitable for areas that are exposed to spilled liquids and high-temperature washdowns. Breweries that prioritize durability and longevity often choose polyurethane concrete flooring for its ability to withstand harsh conditions.

For breweries looking for a cost-effective solution, vinyl flooring is a popular choice. Vinyl flooring is known for its slip resistance and ease of maintenance, making it an attractive option for breweries with high foot traffic. Additionally, vinyl flooring is available in various patterns and colors, allowing breweries to create visually appealing environments that align with their brand image.

When selecting the right flooring for a brewery, it is essential to consider not only the immediate needs but also the long-term implications. Factors such as ease of cleaning, resistance to chemicals, and durability should all be taken into account to ensure that the chosen flooring option can withstand the demands of a busy brewery environment.

Furthermore, breweries may also want to consider the impact of the flooring on their employees’ comfort and safety. Some flooring options, such as epoxy resin and polyurethane concrete, offer excellent slip resistance, reducing the risk of accidents in areas where liquids may be present. This consideration can contribute to a safer working environment for brewery staff.

In conclusion, the choice of flooring for breweries is a decision that should not be taken lightly. By considering factors such as budget, specific brewery needs, and anticipated foot traffic, breweries can select the most suitable flooring option. Whether it be epoxy resin flooring, polyurethane concrete flooring, or vinyl flooring, each option offers its own unique advantages and considerations, ensuring that breweries can create a functional and visually appealing space that can withstand the demands of their operations.

The Process of Installing Brewery Flooring

Installing brewery flooring requires careful planning and execution to ensure proper functionality and durability. Here is a breakdown of the important steps involved:

Pre-Installation Considerations

Prior to installation, it is essential to thoroughly evaluate the existing substrate to ensure it is in good condition. Any cracks, dents, or unevenness should be properly repaired. This evaluation process involves a detailed inspection of the substrate, which includes checking for moisture levels and assessing the structural integrity of the floor.

Additionally, consider factors such as ambient temperature, humidity, and drainage requirements. These factors play a crucial role in determining the type of flooring system that will be suitable for the brewery. For instance, if the brewery operates in an environment with high humidity, it is important to choose a flooring system that is resistant to moisture and can withstand the constant exposure to water.

Installation Steps

The installation process typically involves the application of multiple layers of the chosen flooring system. This may include primer coats, base layers, and topcoats. Each layer must be applied with precision to achieve the desired performance and durability.

Before applying any coatings, the surface needs to be properly prepared. This involves cleaning the substrate thoroughly to remove any dirt, grease, or contaminants that could affect the adhesion of the flooring system. Depending on the condition of the substrate, mechanical preparation methods such as shot blasting or diamond grinding may be necessary to achieve the desired surface profile.

Once the surface is prepared, the primer coat is applied. The primer helps to enhance the adhesion between the substrate and the subsequent layers of the flooring system. It also acts as a barrier to prevent moisture from penetrating the substrate.

After the primer coat has cured, the base layer is applied. This layer provides the main structural support and impact resistance to the flooring system. It is typically a self-leveling compound that is poured and spread evenly over the entire surface. The base layer is then left to cure for a specified period to achieve the desired hardness and strength.

Finally, the topcoat is applied. This layer is responsible for providing the desired aesthetic appearance and additional protection to the flooring system. It is available in various finishes, such as glossy or matte, depending on the brewery’s preference. The topcoat is applied using specialized tools and techniques to ensure an even and smooth finish.

Post-Installation Care

After the flooring is installed, it is essential to allow proper curing time before subjecting it to heavy traffic or cleaning. The curing time can vary depending on the type of flooring system used and the ambient conditions. It is important to follow the manufacturer’s recommendations regarding curing time to ensure the longevity of the flooring system.

Regular inspections should be conducted to identify any signs of wear or damage. This includes checking for any cracks, chips, or delamination of the coating. Any issues should be addressed promptly to prevent further damage and maintain the integrity of the flooring system.

Following the recommended maintenance procedures will help preserve the integrity of the flooring system. This may include regular cleaning using appropriate cleaning agents and methods. It is important to avoid using harsh chemicals or abrasive materials that could potentially damage the coating.

In conclusion, installing brewery flooring is a meticulous process that requires careful planning, proper substrate evaluation, precise installation techniques, and post-installation care. By following these steps and maintaining the flooring system, breweries can ensure a durable and functional floor that can withstand the unique challenges of their operations.

Maintaining Your Brewery Floor

Proper maintenance of your brewery floor is key to extending its lifespan and ensuring a safe working environment. Here are some maintenance strategies to consider:

Routine Cleaning and Maintenance

Regular cleaning is essential to remove debris, spills, and contaminants from the surface. Implementing a daily cleaning routine, including sweeping, mopping, and using appropriate cleaning agents designed for your specific flooring type, will help maintain a clean and sanitary environment.

Dealing with Wear and Tear

Over time, brewery floors may show signs of wear and tear, including scratches, stains, or areas of unevenness. Promptly addressing any issues will prevent further damage and potential safety hazards. Consult with a professional to determine the best repair method for your specific flooring system.

Long-Term Maintenance Strategies

To maximize the lifespan of your brewery floor, consider implementing long-term maintenance strategies such as applying protective coatings or sealants as needed, conducting regular inspections for potential issues, and addressing any repairs promptly.

By understanding the importance of brewery flooring, choosing the right type of flooring system, properly installing it, and maintaining it diligently, you can ensure a safe, efficient, and long-lasting flooring solution for your brewery. Take the time to evaluate your brewery’s specific needs and consult with flooring experts to make an informed decision that will benefit your brewery and its operations for years to come.