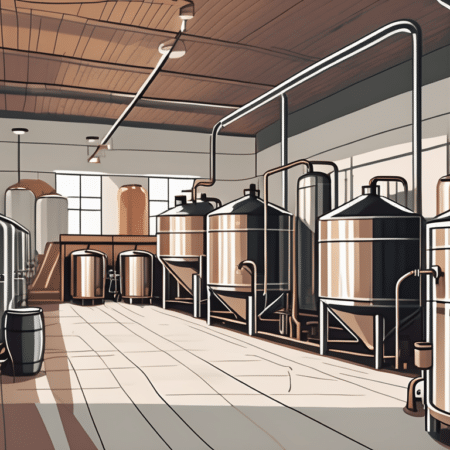

Brewery cleanliness is of utmost importance in ensuring the production of high-quality beer. Not only does it contribute to the taste and consistency of the brew, but it also plays a significant role in ensuring the safety of the facility and its workers. In this comprehensive guide, we will delve into the various aspects of maintaining a clean and safe brewery floor, from understanding the importance of cleanliness to implementing effective cleaning techniques and selecting suitable cleaning agents.

Understanding the Importance of Cleanliness in a Brewery

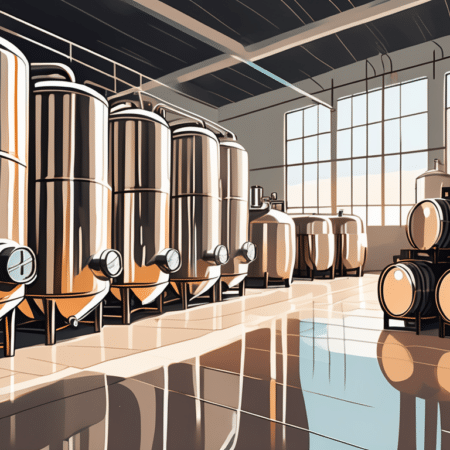

The brewing process involves the interaction of various ingredients, equipment, and microorganisms. Maintaining cleanliness is crucial in preventing contamination and off-flavors that can adversely affect the quality of the beer. A clean brewery not only safeguards the integrity of the brew, but it also ensures the health and safety of both consumers and employees.

When it comes to brewing beer, cleanliness is not just a matter of aesthetics. It plays a vital role in the overall quality of the final product. The presence of contaminants such as bacteria, yeast, and wild microorganisms can introduce unwanted flavors and spoil the beer. These contaminants can come from various sources, including the ingredients themselves, the brewing equipment, and even the air in the brewery. By implementing strict cleanliness protocols, brewers can minimize the risk of contamination and maintain consistency in their brews.

One of the key aspects of maintaining cleanliness in a brewery is proper hygiene. Brewers and brewery workers must adhere to strict hygiene practices to ensure that they do not introduce any contaminants into the brewing process. This includes washing hands thoroughly before handling any ingredients or equipment, wearing clean and sanitized clothing, and regularly cleaning and sanitizing all brewing equipment.

The Role of Hygiene in Brewing Quality Beer

Hygiene is a key factor in brewing quality beer. Contaminants such as bacteria, yeast, and wild microorganisms can introduce unwanted flavors and spoil the beer. By implementing strict cleanliness protocols, brewers can minimize the risk of contamination and maintain consistency in their brews.

Proper hygiene practices also extend to the cleaning and sanitizing of the brewery itself. All surfaces, including floors, walls, and equipment, must be regularly cleaned and sanitized to prevent the buildup of bacteria and other contaminants. This not only ensures the quality of the beer but also extends the lifespan of the brewing equipment.

Furthermore, maintaining a clean brewery is not just about preventing contamination and off-flavors. It also contributes to the overall efficiency of the brewing process. A clean and well-organized brewery allows for smoother operations, reducing the risk of errors and delays. This, in turn, leads to increased productivity and ultimately, better beer.

Safety Concerns Linked to Brewery Cleanliness

Aside from maintaining beer quality, cleanliness in a brewery also contributes to the safety of its workers. Slippery floors, chemical spills, and equipment malfunctions can all pose risks. By keeping the brewery floor clean and well-maintained, potential hazards can be mitigated, creating a safer working environment for employees.

Regular cleaning and maintenance of the brewery equipment also play a crucial role in ensuring the safety of the workers. Faulty or poorly maintained equipment can lead to accidents and injuries. By conducting regular inspections and addressing any issues promptly, brewery owners can minimize the risk of equipment malfunctions and create a safer workplace for their employees.

Additionally, proper cleaning and sanitation practices also help prevent the growth and spread of harmful bacteria and pathogens. This is especially important in a brewery, where the presence of moisture and organic matter can create an ideal environment for the growth of microorganisms. By implementing strict cleanliness protocols, breweries can reduce the risk of foodborne illnesses and ensure the health and safety of both their employees and customers.

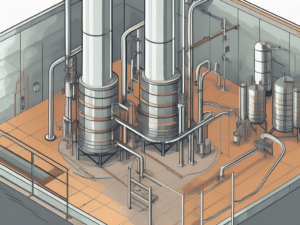

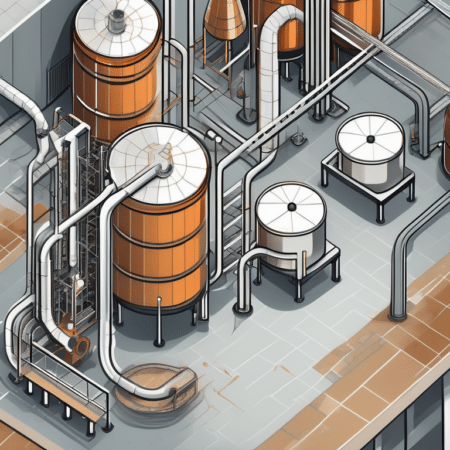

Essential Cleaning Equipment for Brewery Floors

Having the right cleaning equipment is essential for maintaining a clean and hygienic brewery floor. A well-maintained brewery floor not only ensures a safe working environment but also contributes to the quality and consistency of the beer produced. Let’s delve deeper into the key considerations when it comes to choosing the right cleaning tools for your brewery floor.

Choosing the Right Cleaning Tools

When selecting cleaning tools for a brewery floor, there are several factors to consider. Firstly, you need to take into account the type of flooring material in your brewery. Different flooring materials require different cleaning methods and tools. For example, if your brewery floor is made of concrete, you may need heavy-duty scrub brushes or pressure washers to effectively remove stubborn stains and dirt. On the other hand, if your brewery floor is tiled, a combination of mops and brooms may suffice.

Another important consideration is the size of your facility. Larger breweries may require more powerful and efficient cleaning tools to cover a larger surface area. In such cases, investing in industrial-grade pressure washers or floor scrubbers can significantly speed up the cleaning process and ensure thorough cleanliness.

Lastly, it’s crucial to assess the specific cleaning needs of your brewery. Are there any specific areas that require extra attention, such as spill-prone zones or areas with heavy foot traffic? Identifying these areas will help you choose the appropriate cleaning tools and techniques to tackle these challenges effectively.

Maintenance Tips for Cleaning Equipment

Once you have invested in the right cleaning equipment for your brewery floor, it’s important to maintain them properly to ensure their longevity and optimal performance. Regular maintenance is crucial to keep your cleaning tools in good working condition. Here are some maintenance tips to consider:

1. Proper Cleaning and Storage: After each use, make sure to clean your cleaning tools thoroughly. Remove any debris or residue that may have accumulated during the cleaning process. This will prevent the build-up of dirt and bacteria, ensuring that your tools are ready for the next use. Additionally, store your cleaning tools in a clean and dry area to prevent any damage or contamination.

2. Replace Worn-out Parts: Over time, the bristles of brooms and scrub brushes may wear out, reducing their effectiveness. Inspect your cleaning tools regularly and replace any worn-out parts promptly. This will ensure that your tools continue to perform optimally, providing you with the best cleaning results.

3. Regular Equipment Inspection: Periodically inspect your cleaning equipment for any signs of damage or malfunction. Check for loose connections, leaks, or any other issues that may affect the performance of the tools. By identifying and addressing these problems early on, you can prevent further damage and ensure the safety of your cleaning staff.

By following these maintenance tips, you can maximize the efficiency and effectiveness of your cleaning equipment, ultimately leading to a cleaner and safer brewery floor.

Effective Cleaning Techniques for Brewery Floors

A clean brewery floor is not only essential for maintaining a hygienic environment but also for ensuring the quality and safety of the beer produced. To achieve this, a combination of daily cleaning routines and periodic deep cleaning procedures is necessary. Here are some effective cleaning techniques to consider:

Daily Cleaning Routines

Implementing daily cleaning routines is crucial for the ongoing maintenance of a clean brewery floor. Regular sweeping helps remove loose dirt, debris, and other particles that can accumulate throughout the day. Additionally, mopping the floor with a suitable cleaning solution helps eliminate any remaining residue and ensures a thorough clean. It is important to pay special attention to high-touch surfaces, such as taps, handles, and bottling equipment, as these areas are more prone to harboring bacteria and contaminants. Sanitizing these surfaces regularly helps prevent the spread of harmful microorganisms and maintains a safe brewing environment.

Furthermore, daily cleaning routines also involve the proper disposal of waste materials generated during the brewing process. Emptying and cleaning waste bins regularly prevents the buildup of organic matter, which can attract pests and create unpleasant odors. By diligently following these cleaning routines, brewery owners can minimize the risk of contamination and maintain a clean and healthy working environment.

Deep Cleaning Procedures

While daily cleaning routines are effective in preventing the buildup of grime and dirt, periodic deep cleaning procedures are necessary to tackle more stubborn stains, deep-seated dirt, and potential biofilms that may develop over time. Deep cleaning should be performed on a regular basis to ensure the cleanliness and safety of the brewery floor.

One effective deep cleaning technique is the use of specialized cleaning agents. These agents are designed to break down tough stains and remove any residues that regular cleaning methods may not be able to eliminate. It is important to choose cleaning agents that are specifically formulated for brewery floors to avoid any potential damage to the surface or contamination of the beer.

In addition to specialized cleaning agents, power washing can be employed to thoroughly clean the brewery floor. Power washing utilizes high-pressure water jets to dislodge and remove dirt, grime, and stains. This method is particularly effective for outdoor brewery areas or spaces with heavy foot traffic where dirt and debris can accumulate more rapidly.

Another deep cleaning technique is steam cleaning. Steam cleaning uses high-temperature steam to sanitize and disinfect surfaces. This method not only removes dirt and stains but also eliminates bacteria and other microorganisms that may be present on the brewery floor. Steam cleaning is an eco-friendly option as it does not require the use of harsh chemicals.

When performing deep cleaning procedures, it is important to follow manufacturer instructions and safety guidelines to ensure proper usage of cleaning agents and equipment. Additionally, it is advisable to schedule deep cleaning during periods when the brewery is less active to minimize disruption to daily operations.

By incorporating these effective cleaning techniques into their brewery maintenance routine, owners can ensure a clean and safe environment for brewing operations. Regular cleaning not only enhances the overall appearance of the brewery but also contributes to the production of high-quality beer that meets the highest standards of taste and hygiene.

Selecting Suitable Cleaning Agents for Breweries

Selecting the right cleaning agents is critical for maintaining a clean and safe brewery floor. Consider the following:

Understanding Different Types of Cleaning Agents

There are various types of cleaning agents available, each designed for specific applications. It is important to understand the different types of cleaning agents, their compatibility with brewery surfaces, and their effectiveness against specific contaminants. This knowledge will help in selecting the most suitable cleaning agents for maintaining a clean brewery floor.

Environmentally Friendly Cleaning Solutions

In addition to effectiveness, it is important to consider the environmental impact of cleaning agents used in breweries. Choosing eco-friendly cleaning solutions helps minimize the pollution and negative impact on ecosystems. Look for cleaning agents that are biodegradable, non-toxic, and have low volatile organic compounds (VOC) content.

Implementing Safety Measures During Cleaning

Ensuring the safety of cleaning staff is paramount during the cleaning process. Here are some safety measures to consider:

Protective Gear for Cleaning Staff

Equipping cleaning staff with appropriate personal protective equipment (PPE) is essential for their safety. This includes gloves, safety glasses, and non-slip footwear. Proper training on the correct use of PPE should also be provided to ensure its effectiveness.

Safe Handling of Cleaning Agents

Cleaning agents can be hazardous if handled incorrectly. It is crucial to provide clear instructions on the safe handling, storage, and disposal of cleaning agents. Staff should be trained on proper chemical handling procedures to minimize the risk of accidents and injuries.

By following this comprehensive guide, brewery owners and staff can ensure a clean and safe environment for brewing quality beer. Implementing proper cleanliness protocols, using suitable cleaning equipment and agents, and prioritizing safety measures will contribute to the overall success and reputation of the brewery.