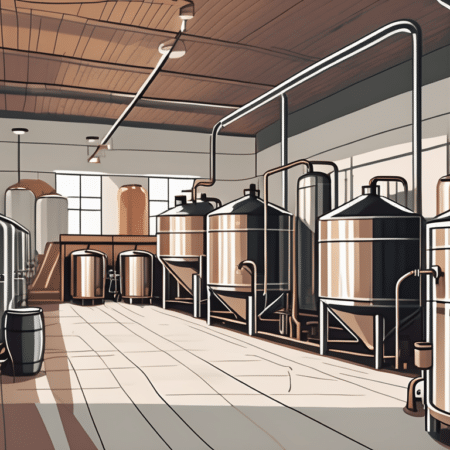

In the brewing industry, the importance of a sturdy and reliable floor cannot be overstated. Brewery floor paint plays a crucial role in maintaining a safe and productive brewing environment. Not only does it enhance the aesthetic appeal of the brewery, but it also provides protection against spills, chemicals, and heavy equipment. Understanding the significance of brewery floor paint is vital for brewery owners and operators who want to create a conducive workspace for their brewing operations.

Understanding the Importance of Brewery Floor Paint

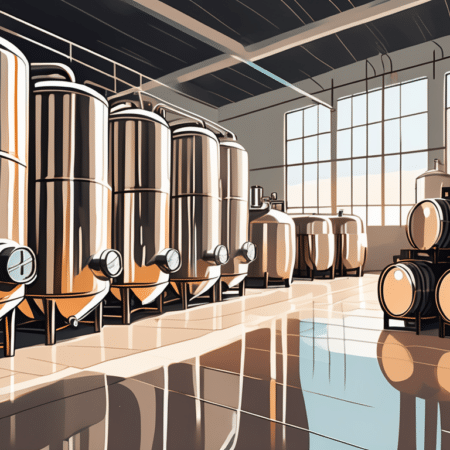

When it comes to brewery floors, the stakes are high. Floors in breweries endure constant foot traffic, heavy equipment, and exposure to moisture, chemicals, and temperature fluctuations. Without proper protection, these factors can not only deteriorate the floor but also jeopardize the quality and safety of the beer being produced. This is where brewery floor paint steps in to safeguard both the floor and the product.

But let’s dive deeper into the world of brewery floor paint and explore its role in ensuring a safe and efficient brewing environment.

The Role of Floor Paint in a Brewery

Brewery floor paint serves as a protective barrier between the brewing environment and the underlying surface. It goes beyond mere aesthetics and plays a crucial role in maintaining the integrity of the brewery floor.

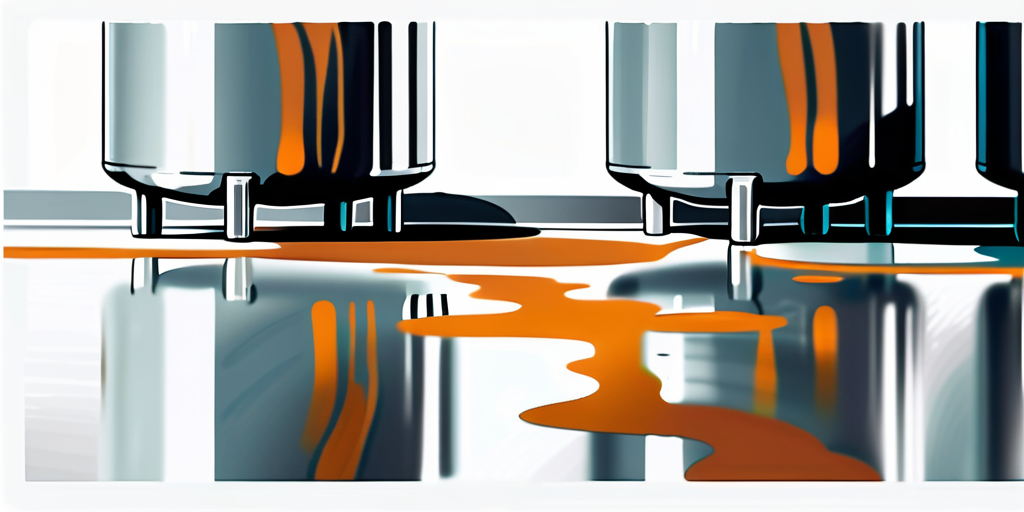

One of the primary functions of brewery floor paint is to prevent the penetration of moisture, chemicals, and dirt. As breweries deal with constant exposure to water and various cleaning agents, the floor paint acts as a shield, preventing these substances from seeping into the concrete or other flooring materials. By doing so, it helps to minimize the growth of bacteria or other contaminants that could compromise the quality of the beer being produced.

Additionally, brewery floor paint provides a durable and easy-to-clean surface. The constant movement of heavy equipment, such as forklifts and keg trolleys, can take a toll on the floor. However, with the right paint, the floor can withstand the impact and abrasion caused by these activities. Moreover, the smooth and seamless finish of the paint makes it easier to clean spills, preventing any potential hazards or cross-contamination.

Furthermore, brewery floor paint enhances the overall safety of the brewery by reducing the risk of slips, trips, and falls. The brewery environment is often wet and prone to spills, making it a potential breeding ground for accidents. However, with the right type of paint, the floor can be made slip-resistant, providing a secure footing for brewery staff and visitors alike. This helps to create a safer working environment and minimizes the chances of injuries.

Why Quality Matters in Brewery Floor Paint

When it comes to brewery floor paint, quality should never be compromised. Inferior paints may seem like a cost-effective option initially, but they can lead to significant problems in the long run.

In a demanding environment like a brewery, where the floor is subjected to constant abuse, using low-quality paint can result in chipping, peeling, or discoloration. This not only affects the aesthetics of the brewery but also compromises the integrity of the floor. Chipped or peeling paint can create areas where moisture and contaminants can penetrate, leading to potential bacterial growth or contamination of the beer.

Moreover, low-grade paints may not adhere properly to the floor surface, leading to premature failure and the need for frequent touch-ups or reapplication. This can be time-consuming and costly, disrupting the brewing process and impacting productivity.

Choosing a reputable brand and a paint specifically designed for brewery floors is crucial for ensuring long-lasting performance. High-quality brewery floor paints are formulated to withstand the harsh conditions of a brewery, including temperature fluctuations, chemical exposure, and heavy foot traffic. They offer excellent adhesion, durability, and resistance to chipping, peeling, or discoloration, providing a reliable and long-lasting solution for brewery floors.

So, when it comes to protecting your brewery floor and ensuring the quality and safety of your beer, investing in high-quality brewery floor paint is a decision that pays off in the long run.

Different Types of Brewery Floor Paint

When it comes to choosing the right floor coating for breweries, there are several options available, each with its own unique characteristics and suitability for different areas of the brewing facility. Let’s take a closer look at some of the most commonly used types of brewery floor paint.

Epoxy Floor Coatings

Epoxy floor coatings have gained immense popularity in the brewing industry, and for good reason. These coatings are known for their exceptional durability and resistance to chemicals, impacts, and abrasion. They provide a seamless, non-porous surface that is not only easy to clean but also maintain. This is particularly important in breweries where spills and accidents are bound to happen. With epoxy coatings, you can rest assured that your brewery floor will be able to withstand the daily rigors of the brewing process.

One of the key advantages of epoxy coatings is their excellent adhesion to the substrate. This means that once applied, the coating forms a strong bond with the underlying surface, ensuring long-term performance and preventing any peeling or flaking. This is especially crucial in breweries where heavy equipment and machinery are constantly in use.

Polyurethane Floor Coatings

Polyurethane floor coatings are another popular choice for breweries, thanks to their outstanding resistance to chemical attack. Breweries often deal with various acids and chemicals during the brewing process, and polyurethane coatings are specifically designed to withstand such harsh environments. They provide a tough and flexible surface that can endure thermal shock and heavy loads, making them ideal for areas where heavy equipment or barrels are frequently moved around.

In addition to their chemical resistance, polyurethane coatings are also UV stable, which means they can be used in outdoor brewery areas without the risk of fading or discoloration due to sunlight exposure. This makes them a versatile option for breweries that have outdoor spaces or patio areas where customers can enjoy their freshly brewed beverages.

Acrylic Floor Coatings

For breweries that require moderate chemical and abrasion resistance at a more cost-effective price point, acrylic floor coatings are a popular choice. These coatings offer a glossy finish that enhances the overall aesthetics of the brewery floor. They can be easily recoated or repaired, allowing for easy maintenance and ensuring that your brewery floor always looks its best.

Acrylic coatings are typically used in areas with low to medium traffic, such as office spaces or tasting rooms. They can also be applied as a topcoat over other floor coatings to provide an additional layer of protection and enhance the overall durability of the floor surface.

Choosing the right type of brewery floor paint is essential to ensure the longevity and performance of your brewery floor. Consider factors such as the specific needs of your brewing facility, the level of chemical exposure, and the amount of foot and equipment traffic when making your decision. With the right floor coating, you can create a safe, durable, and visually appealing environment for both your brewing process and your customers.

Choosing the Right Brewery Floor Paint

When embarking on a brewery floor paint project, several factors should be considered to ensure the best results.

Factors to Consider

Firstly, it is essential to evaluate the specific requirements of the brewing facility. Factors such as the type of brewing operations, the traffic intensity, and the presence of chemicals or moisture should guide the selection process. Additionally, the climate and temperature variations in the brewery’s location should be taken into account to choose a paint that can withstand these conditions.

Paint Durability and Maintenance

Durability is a crucial aspect to consider when selecting brewery floor paint. The paint should be able to endure the rigorous conditions of a brewery without chipping or wearing down. Additionally, its maintenance requirements should be manageable and not overly time-consuming.

Cost Considerations

While it may be tempting to opt for the least expensive paint option, it is important to weigh the long-term costs against the upfront price. Investing in a high-quality, durable paint may incur a higher initial cost but can save money in the long run by reducing the need for frequent repairs or replacements.

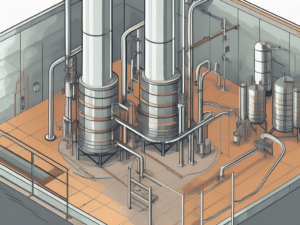

The Application Process of Brewery Floor Paint

Proper application is crucial to achieve the desired results and ensure the longevity of the brewery floor paint. Following a systematic approach will help optimize the paint’s performance.

Preparing the Brewery Floor

The first step in the application process is to prepare the brewery floor adequately. This involves thoroughly cleaning the surface, removing any existing coatings or contaminants, and repairing any cracks or imperfections. A clean and smooth substrate will allow the paint to adhere properly and result in a more even finish.

Applying the Paint

Once the floor is prepared, the paint can be applied. It is recommended to follow the manufacturer’s instructions regarding mixing ratios, application tools, and recommended drying conditions. Depending on the paint type, it may require multiple coats for optimal performance. Proper ventilation should be maintained during the application process to ensure a safe working environment.

Drying and Curing Time

After the paint has been applied, it is crucial to allow sufficient drying and curing time before subjecting the floor to heavy traffic or chemical exposure. Following the manufacturer’s guidelines regarding drying and curing times is essential to avoid premature damage to the paint. It is important to note that curing times may vary depending on factors such as temperature and humidity.

In conclusion, brewery floor paint is a critical component of any brewing facility. Understanding its importance, selecting the right type of paint, and following proper application procedures are all essential steps to ensure a durable and safe brewery floor. By investing in high-quality paint and maintaining the floor regularly, brewery owners can create an environment that promotes productivity, efficiency, and the production of high-quality beer.