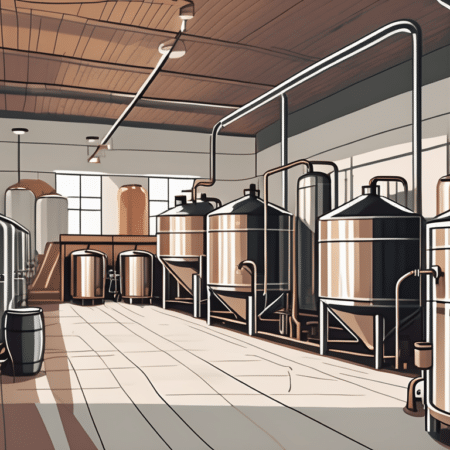

Breweries require flooring that can withstand heavy foot traffic, constant spills, and the presence of corrosive substances. Epoxy floor coatings have emerged as the ideal solution for brewery floors, providing durability, chemical resistance, and an attractive finish. In this ultimate guide, we will delve into the importance of brewery floor coatings, the different types of epoxy coatings suitable for breweries, the application process, maintenance and care, as well as the cost evaluation of epoxy floors.

Understanding the Importance of Brewery Floor Coatings

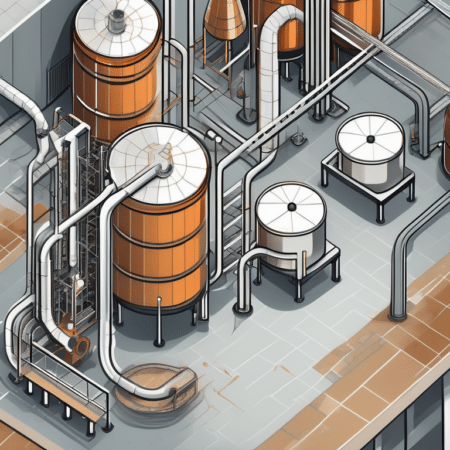

When it comes to brewery floors, the importance of having a reliable coating cannot be overstated. Brewery floors are subjected to unique challenges due to the presence of water, chemicals, and the movement of heavy equipment. Epoxy coatings offer exceptional resistance to these factors, ensuring a safe and clean working environment for brewery staff.

But what exactly makes epoxy coatings so crucial for brewery floors? Let’s delve deeper into the role of epoxy in brewery floors and explore the key features that make them an ideal choice.

The Role of Epoxy in Brewery Floors

Epoxy plays a vital role in brewery floors by creating a seamless and impermeable surface that prevents liquids from seeping into the underlying concrete. This not only prevents the growth of bacteria and mold but also eliminates the risk of contamination in the brewing process.

Imagine a scenario where a brewery floor lacks proper coating. Spills and leaks from brewing ingredients, cleaning chemicals, and water can seep into the porous concrete, creating an ideal breeding ground for bacteria and mold. Not only does this compromise the cleanliness of the brewery, but it also poses a serious health risk to both the staff and the quality of the beer being produced.

By applying epoxy coatings, brewery owners can ensure that their floors remain impervious to liquid penetration. This protective layer acts as a barrier, preventing any substances from seeping into the concrete. As a result, the risk of bacterial growth and contamination is significantly reduced, ensuring a hygienic brewing environment.

Furthermore, epoxy coatings enhance the floor’s resistance to abrasion, impact, and UV radiation. In a bustling brewery where heavy equipment is constantly being moved around, the floor is prone to wear and tear. Epoxy coatings provide an extra layer of protection, ensuring that the floor can withstand the daily demands of a busy brewery without deteriorating.

Key Features of an Ideal Brewery Floor

An ideal brewery floor should possess certain characteristics to ensure optimal performance. These include high chemical resistance, slip resistance, thermal shock resistance, and durability. Epoxy coatings exhibit all of these qualities, making them the preferred choice for breweries.

Chemical resistance is of utmost importance in a brewery setting, as various chemicals are used for cleaning, sanitizing, and brewing processes. Epoxy coatings are designed to withstand exposure to a wide range of chemicals, ensuring that the floor remains intact and unaffected by the harsh substances used in the brewery.

Slip resistance is another crucial factor to consider when it comes to brewery floors. With the presence of water and spilled liquids, the floor can become slippery, posing a safety hazard for brewery staff. Epoxy coatings can be customized with anti-slip additives, providing a textured surface that enhances traction and reduces the risk of slips and falls.

Thermal shock resistance is also essential in a brewery, where hot liquids and steam are frequently encountered. Epoxy coatings have excellent thermal shock resistance, meaning they can withstand sudden temperature changes without cracking or delaminating.

Lastly, durability is a key feature that brewery owners seek in their floors. A brewery floor needs to withstand heavy foot traffic, the movement of equipment, and the occasional accidental impact. Epoxy coatings are known for their durability, ensuring that the floor remains in top condition even under demanding conditions.

In conclusion, epoxy coatings play a vital role in brewery floors by providing a seamless and impermeable surface that prevents liquid penetration, bacterial growth, and contamination. They also enhance the floor’s resistance to abrasion, impact, and UV radiation. With their high chemical resistance, slip resistance, thermal shock resistance, and durability, epoxy coatings are the ideal choice for brewery owners looking to maintain a safe and hygienic working environment.

Types of Epoxy Coatings Suitable for Breweries

When it comes to brewery floors, having the right type of epoxy coating is essential. There are several options available, each offering unique advantages and characteristics. Let’s explore the three most common types in more detail:

Self-Leveling Epoxy Coatings

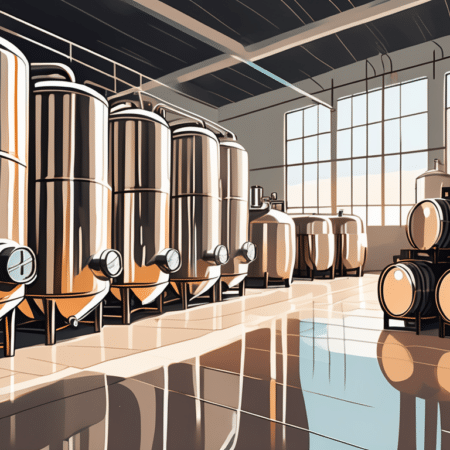

One of the most popular choices for breweries is self-leveling epoxy coatings. As the name suggests, this type of coating creates a smooth and seamless surface. This is particularly beneficial in a brewery setting where spills are frequent. The self-leveling properties ensure that any liquid is quickly and efficiently dispersed, minimizing the risk of accidents and making cleaning a breeze.

But it’s not just the seamless surface that makes self-leveling epoxy coatings ideal for breweries. These coatings are also highly resistant to chemicals, ensuring that any spills or cleaning agents won’t cause damage or discoloration. This durability is crucial in an environment where various liquids, such as beer, water, and cleaning solutions, are constantly present.

Additionally, self-leveling epoxy coatings offer excellent abrasion resistance. This means that even under heavy equipment and foot traffic, the floor remains intact and maintains its aesthetic appeal. Breweries often have a lot of activity, with barrels being moved around, kegs being rolled, and employees bustling about. With a self-leveling epoxy coating, the floor can withstand the demands of a busy brewery without showing signs of wear and tear.

High Build Epoxy Coatings

For brewery floors that require extra protection, high build epoxy coatings are an excellent choice. This type of coating provides enhanced thickness, offering superior durability and impact resistance. The added thickness creates a robust barrier that can withstand heavy loads and potential impacts from equipment or dropped objects.

One of the advantages of high build epoxy coatings is their customizable options for texture. Breweries often have areas that require extra safety precautions, such as walkways, ramps, or areas prone to spills. With high build epoxy coatings, breweries can create a non-slip surface in these specific areas, reducing the risk of accidents and ensuring the safety of employees and visitors.

Moreover, high build epoxy coatings are also highly resistant to chemicals, making them suitable for brewery environments. They can withstand exposure to various substances, including cleaning agents, brewing ingredients, and spilled beverages, without suffering any damage or degradation. This chemical resistance ensures that the floor remains in optimal condition for years to come.

Epoxy Mortar Systems

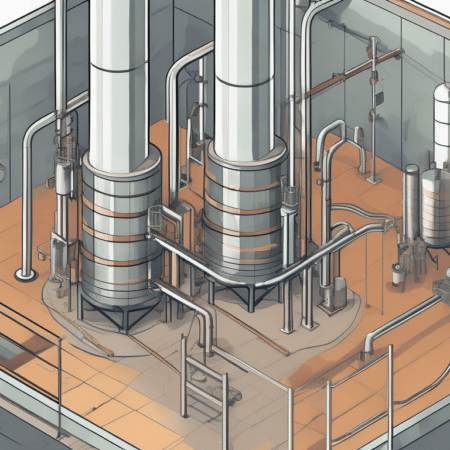

When it comes to demanding environments, epoxy mortar systems are the go-to choice for breweries. This type of coating consists of a combination of epoxy resin and aggregates, such as quartz or sand, which creates a highly durable and chemical-resistant floor surface.

Epoxy mortar systems are designed to withstand heavy impacts, thermal shock, and harsh chemicals commonly found in breweries. In a bustling brewery, accidents can happen, and heavy equipment can cause significant impacts on the floor. With an epoxy mortar system, the floor is protected against these impacts, ensuring its longevity and structural integrity.

Furthermore, breweries often deal with extreme temperature changes, especially during the brewing process. Epoxy mortar systems can handle thermal shock, meaning they won’t crack or deteriorate when exposed to rapid temperature fluctuations. This is essential for maintaining a reliable and long-lasting floor in a brewery setting.

Lastly, the chemical resistance of epoxy mortar systems is unparalleled. Breweries use a variety of chemicals, such as cleaning agents, sanitizers, and brewing ingredients, which can be highly corrosive. With an epoxy mortar system, the floor is shielded from these chemicals, preventing any damage or deterioration that could compromise the safety and hygiene of the brewery.

Choosing the right type of epoxy coating for a brewery is crucial for maintaining a safe, durable, and visually appealing floor. Whether it’s a self-leveling epoxy coating, high build epoxy coating, or epoxy mortar system, each option offers unique benefits that cater to the specific needs of a brewery environment.

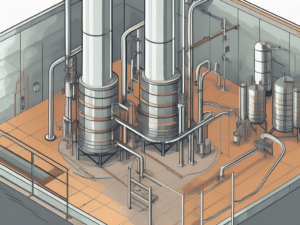

The Process of Applying Epoxy on Brewery Floors

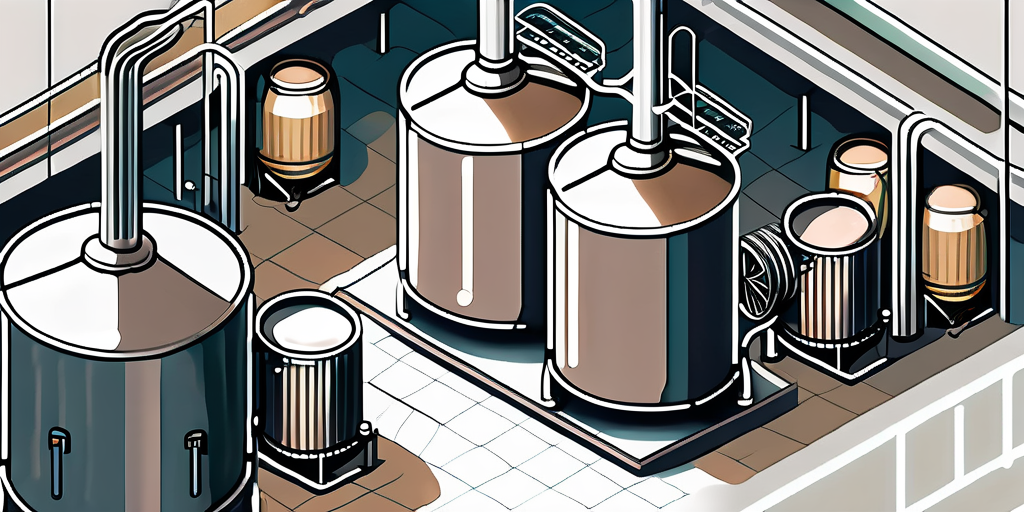

Proper surface preparation is crucial to ensure a successful epoxy application. Before applying epoxy on brewery floors, the surface must be thoroughly cleaned and any cracks or imperfections repaired. This helps to ensure proper adhesion and prolong the lifespan of the epoxy coating.

Surface Preparation for Epoxy Application

The surface preparation process typically involves cleaning the floor with industrial-grade cleaners and degreasers to remove any grease, oil, or contaminants. After cleaning, the floor may require mechanical surface preparation, such as shot blasting or diamond grinding, to create a rough surface for the epoxy to adhere to.

Steps in the Epoxy Application Process

The epoxy application process consists of several steps to ensure a durable and long-lasting finish. These steps typically include priming the floor, applying the epoxy coating, and adding a topcoat for additional protection. Each layer is carefully applied, taking into consideration the manufacturer’s instructions for mixing, pot life, and curing times.

Maintenance and Care for Epoxy Brewery Floors

Although epoxy floors are known for their durability, proper maintenance and care are essential for extending their lifespan. Here are some tips for keeping your epoxy brewery floors in top condition:

Cleaning Techniques for Epoxy Floors

To clean epoxy floors in breweries, it is recommended to use non-abrasive, pH-neutral cleaners. Avoid harsh chemicals that can damage the epoxy coating. Regular sweeping and mopping are usually sufficient for day-to-day maintenance, but periodic deep cleaning may be necessary to remove stubborn stains.

Preventive Measures for Long-Lasting Epoxy Floors

Implementing preventive measures can greatly contribute to the longevity of epoxy brewery floors. This includes placing mats or rugs in high-traffic areas to prevent excessive wear on the epoxy surface. It is also important to promptly clean up any spills to prevent staining or damage to the coating. Finally, regular inspections and maintenance should be conducted to address any minor issues before they escalate.

Evaluating the Cost of Epoxy Brewery Floors

While the initial cost of installing epoxy floors in breweries may be higher than alternative flooring solutions, the long-term financial benefits outweigh the initial investment. Factors influencing the cost of epoxy flooring include the size of the brewery, the condition of the existing floor, and any specific customization requirements.

Factors Influencing the Cost of Epoxy Flooring

The size of the brewery and the complexity of the floor layout can impact the overall cost of epoxy flooring. Additionally, any repairs or surface preparation required prior to coating installation can increase the cost. Customization options, such as decorative flakes or patterns, may also affect the overall price.

Long-Term Financial Benefits of Epoxy Floors

Although epoxy floors may have a higher upfront cost, they offer significant long-term financial benefits. Epoxy coatings are extremely durable and can withstand heavy wear and tear, reducing the need for frequent repairs or replacements. Additionally, their chemical resistance helps to prevent damage from spills, saving on cleaning and maintenance costs in the long run.

In conclusion, epoxy floor coatings are the ultimate solution for brewery floors, providing durability, chemical resistance, and a visually appealing finish. By understanding the importance of brewery floor coatings, exploring the different types of epoxy coatings suitable for breweries, following the correct application process, implementing proper maintenance and care, and evaluating the long-term financial benefits, breweries can make informed decisions when it comes to their flooring needs. Invest in epoxy coatings for your brewery floors and enjoy a safe, reliable, and long-lasting flooring solution.