Epoxy floor preparation is a vital step in achieving a durable and high-quality epoxy floor finish. Whether you are planning to install an epoxy coating in your garage, basement, or commercial space, proper preparation is crucial for ensuring the longevity and performance of your flooring system. This ultimate guide will provide you with a comprehensive understanding of the various aspects of epoxy floor prep, including its importance, basic principles, necessary tools and materials, step-by-step procedures, safety measures, and common mistakes to avoid.

Understanding Epoxy Floor Preparation

Before diving into the details, it is essential to grasp the concept of epoxy floor preparation and its significance. Properly preparing the surface before applying the epoxy coating ensures proper adhesion and eliminates potential issues such as delamination, bubbling, and premature wear. It involves a series of steps that aim to clean, repair, and prime the floor for optimal adherence and performance.

When it comes to epoxy floor preparation, attention to detail is key. The success of your epoxy flooring project relies heavily on the thoroughness of the preparation process. By taking the time to properly prepare the surface, you can ensure a long-lasting, visually appealing, and durable epoxy floor.

The Importance of Proper Epoxy Floor Prep

The adage “preparation is key” holds true for epoxy floor installation. By neglecting or inadequately completing the preparation process, you risk compromising the durability and aesthetic appeal of your epoxy floor. Proper surface preparation not only enhances the bond between the concrete substrate and the epoxy coating but also improves the overall appearance and longevity of the finished floor system. Skipping or rushing through this crucial step can lead to costly repairs or even complete floor failure in the future.

One of the primary reasons why proper epoxy floor preparation is crucial is to ensure optimal adhesion. Without proper surface preparation, the epoxy coating may not bond effectively to the substrate, leading to delamination or peeling over time. By thoroughly cleaning and repairing the floor, you create a clean and sound surface for the epoxy to adhere to, maximizing its performance and longevity.

In addition to adhesion, proper floor preparation also helps eliminate potential issues such as bubbling and premature wear. By addressing any existing imperfections, cracks, or unevenness in the concrete substrate, you create a smooth and level surface for the epoxy coating. This ensures that the epoxy can be applied evenly and without any air pockets, reducing the risk of bubbling or blistering. Furthermore, by repairing any damaged areas, you prevent premature wear and extend the lifespan of your epoxy floor.

Basic Principles of Epoxy Floor Preparation

To understand the intricacies of epoxy floor preparation, it is essential to familiarize yourself with the basic principles involved. These principles include assessing the concrete condition, identifying moisture issues, evaluating surface contaminants, and achieving the desired profile for optimal epoxy adhesion. Each principle plays a crucial role in ensuring a successful epoxy flooring installation.

Assessing the concrete condition is the first step in epoxy floor preparation. This involves inspecting the concrete substrate for any cracks, spalling, or other damage that may affect the adhesion of the epoxy coating. By identifying and addressing these issues, you can ensure a solid foundation for the epoxy floor.

Moisture is another critical factor to consider during epoxy floor preparation. Excessive moisture in the concrete can lead to adhesion failure and other problems such as blistering or peeling. It is essential to test the moisture content of the concrete and take appropriate measures to mitigate any moisture issues before applying the epoxy coating.

Surface contaminants, such as dirt, oil, grease, or previous coatings, can also hinder the adhesion of the epoxy coating. Thoroughly cleaning the surface and removing any contaminants is crucial for achieving optimal adhesion and a flawless finish. This may involve using specialized cleaning agents, degreasers, or mechanical methods such as shot blasting or diamond grinding.

Lastly, achieving the desired profile on the concrete surface is essential for optimal epoxy adhesion. The profile refers to the roughness or texture of the surface, which allows the epoxy to mechanically bond to the substrate. Depending on the specific epoxy system being used, achieving the correct profile may involve methods such as acid etching, shot blasting, or diamond grinding.

By following these basic principles of epoxy floor preparation, you can ensure a solid foundation for your epoxy flooring system. Taking the time and effort to properly prepare the surface will pay off in the long run, resulting in a beautiful, durable, and long-lasting epoxy floor.

Tools and Materials Needed for Epoxy Floor Prep

Equipping yourself with the right tools and materials is vital for a smooth and efficient epoxy floor preparation process. By having the necessary tools at your disposal, you can ensure that each step of the preparation is executed correctly, saving you time and effort in the long run.

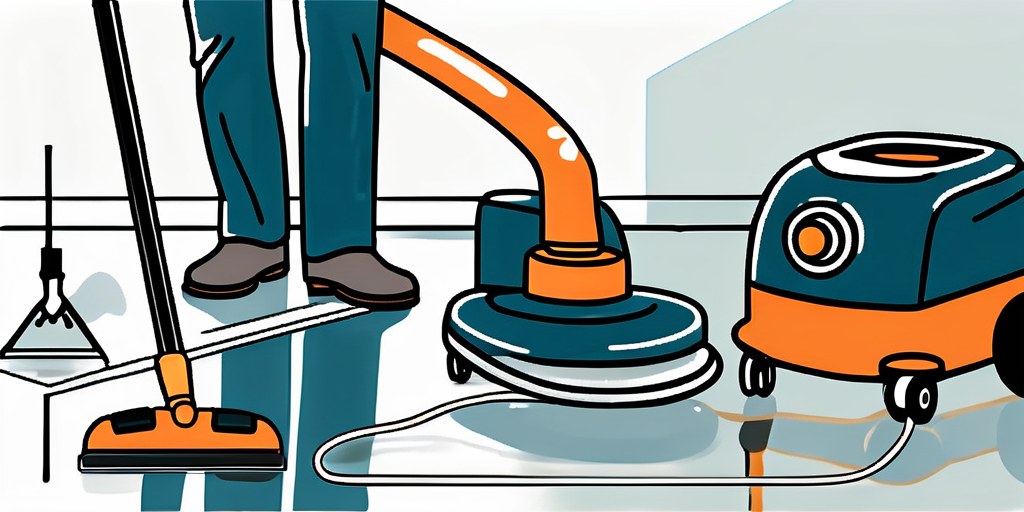

When it comes to epoxy floor preparation, there are several essential tools that you should have on hand. One of the most important tools is a floor grinder or shot blaster. This powerful machine is used to remove any existing coatings, stains, or imperfections from the concrete surface, creating a clean and smooth substrate for the epoxy coating. Additionally, a vacuum cleaner is essential for removing dust and debris generated during the grinding process, ensuring a clean work area.

Another tool that is crucial for epoxy floor preparation is a scrub brush. This brush is used to scrub the concrete surface with a concrete cleaner or degreaser, removing any dirt, oil, or grease that could hinder the adhesion of the epoxy coating. A squeegee is also handy for removing excess water or cleaning solutions from the floor, leaving it dry and ready for the next step.

When it comes to filling cracks and imperfections in the concrete, a putty knife and trowel are indispensable tools. These tools allow you to apply patching compounds or epoxy fillers to repair any damaged areas, ensuring a smooth and level surface. It is important to note that proper safety equipment, such as gloves and goggles, should always be worn when working with these materials to protect yourself from any potential hazards.

Choosing the Right Materials for Epoxy Floor Prep

Alongside the tools, selecting the right materials for epoxy floor preparation is equally important. This includes concrete cleaners, degreasers, patching compounds, and epoxy primers. Each material serves a specific purpose in the preparation process and ensures optimal adhesion and longevity of the epoxy floor.

Concrete cleaners are designed to remove dirt, grime, and stains from the concrete surface, preparing it for the application of the epoxy coating. These cleaners come in various formulations, including alkaline-based or acid-based, depending on the specific needs of your project. It is essential to choose a cleaner that is compatible with your concrete surface to achieve the best results.

Degreasers, on the other hand, are specifically formulated to remove oil, grease, and other contaminants that can interfere with the adhesion of the epoxy coating. These powerful solutions penetrate deep into the concrete, breaking down and lifting away stubborn stains, ensuring a clean and oil-free surface.

Patching compounds play a crucial role in repairing cracks, divots, or other imperfections in the concrete. These compounds are typically made of a blend of cement, aggregates, and bonding agents, providing a durable and long-lasting repair. By filling in these imperfections, you create a smooth and even surface for the epoxy coating, preventing any irregularities from showing through.

Finally, epoxy primers are essential for promoting adhesion between the concrete surface and the epoxy coating. These primers penetrate into the concrete, creating a strong bond that ensures the longevity and durability of the epoxy floor. They also help to seal the concrete, preventing moisture vapor transmission, and enhancing the overall performance of the epoxy system.

By carefully selecting the right tools and materials for epoxy floor preparation, you can ensure that your project is off to a great start. Proper preparation is key to achieving a flawless and long-lasting epoxy floor that will enhance the beauty and functionality of your space.

Steps in Epoxy Floor Preparation

Now that you have a thorough understanding of the importance, principles, tools, and materials involved in epoxy floor preparation, let’s dive into the step-by-step process. By following these steps diligently, you can achieve a properly prepared surface ready for the application of your epoxy coating.

Cleaning and Clearing the Floor Area

The first step in epoxy floor preparation is thoroughly cleaning and clearing the floor area. This involves removing any furniture, debris, or loose materials that may hinder the preparation process. Additionally, a deep cleaning with a concrete cleaner or degreaser will eliminate any contaminants that could compromise the epoxy bond.

Repairing and Smoothing the Floor Surface

Once the floor is clean, repair any cracks, divots, or uneven areas using a patching compound. Smoothing out the floor surface ensures a level substrate for optimal epoxy adhesion and prevents any imperfections from showing through the finished coating.

Priming the Floor for Epoxy Application

The final step in preparing the floor for epoxy is applying a primer. The primer enhances the bond between the concrete and the epoxy coating, ensuring better adhesion and durability. Following manufacturer instructions, apply the primer evenly on the entire floor surface using a roller or brush.

Safety Measures in Epoxy Floor Preparation

While epoxy floor preparation is essential for achieving a successful floor installation, it is equally important to prioritize safety throughout the process. Being aware of potential hazards and utilizing proper safety measures ensures a risk-free environment for both you and your flooring project.

Protective Gear for Epoxy Floor Prep

Wearing appropriate protective gear is crucial when working with epoxy and other chemicals. This includes gloves, safety goggles, and respiratory masks. These protective measures safeguard against potential skin irritation, eye damage, and inhalation of harmful fumes.

Handling Epoxy and Other Chemicals Safely

Proper handling and storage of epoxy and other chemicals are vital for both personal safety and the effectiveness of the products. Follow the manufacturer’s instructions when mixing and applying epoxy, and ensure proper ventilation during the process. Avoid direct skin contact and clean any spills promptly to prevent accidents.

Common Mistakes in Epoxy Floor Preparation

Even with a thorough guide and attention to detail, mistakes can still occur during the epoxy floor preparation process. Being aware of these common mistakes can help you avoid potential pitfalls and ensure a successful epoxy flooring installation.

Avoiding Inadequate Surface Preparation

Rushing or skipping the surface preparation stage is one of the most common mistakes when installing an epoxy floor. Neglecting to clean, repair, or prime the floor properly can lead to adhesion failure and a compromised flooring system. Take your time and follow each step of the preparation process diligently for optimal results.

Preventing Improper Mixing of Epoxy Materials

Improperly mixing epoxy materials is another common mistake that can impact the performance and appearance of your finished floor. Follow the manufacturer’s instructions closely, ensuring accurate measurements and thorough mixing to achieve a well-blended epoxy mixture. Inadequate mixing can result in uneven curing and decreased durability.

In conclusion, proper epoxy floor preparation is the foundation for a long-lasting and visually appealing flooring system. By understanding the importance, principles, tools, materials, steps, safety measures, and common mistakes involved in the preparation process, you can ensure the success of your epoxy floor installation. Take the time to prepare your floor correctly, and you will reap the benefits of a durable and stunning epoxy-coated surface for years to come.