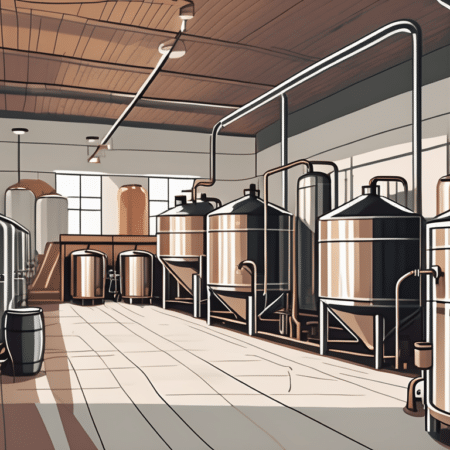

Welcome to the ultimate guide to commercial flooring for breweries. In this comprehensive article, we will delve into the importance of brewery flooring, the different types of flooring available, their pros and cons, the installation process, and how to maintain your brewery flooring for optimal performance.

Understanding the Importance of Brewery Flooring

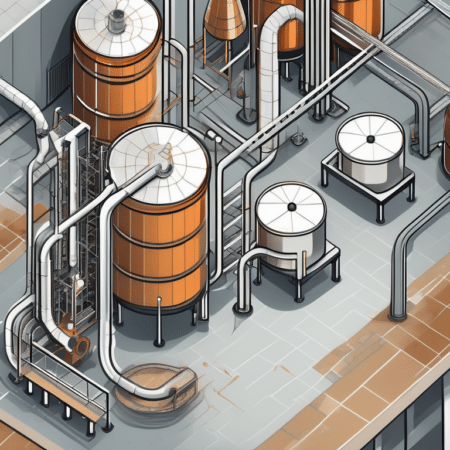

Brewery flooring plays a crucial role in the overall operations of a brewery. It not only provides a durable and safe surface for employees to work on but also contributes to the hygiene and cleanliness of the facility. The right flooring choice can prevent slips, falls, and accidents, ensuring a safe working environment for everyone.

When it comes to brewery operations, the flooring must be able to withstand heavy machinery, constant foot traffic, and exposure to moisture, chemicals, and temperature fluctuations. It should be resistant to impact, abrasion, and chemical spills. Additionally, the flooring should be easy to clean and maintain to meet strict hygiene standards.

One important aspect to consider when choosing brewery flooring is its durability. The constant movement of heavy equipment, such as forklifts and keg trolleys, can put a significant amount of stress on the floor. Therefore, the flooring material must be able to withstand this constant pressure without cracking or deteriorating.

Slip resistance is another crucial factor to consider. Brewery floors are often exposed to liquids, such as water, beer, and cleaning solutions, which can make the surface slippery. To prevent accidents, it is essential to choose a flooring material that offers excellent slip resistance, even when wet.

Chemical resistance is also vital in brewery flooring. Breweries use a variety of chemicals, including cleaning agents, sanitizers, and brewing ingredients, which can potentially damage the floor if not properly protected. The flooring material should be able to withstand exposure to these chemicals without deteriorating or staining.

Easy cleaning and maintenance are essential for maintaining a high level of hygiene in a brewery. The flooring should be resistant to stains and easy to clean, allowing for quick and efficient removal of spills and contaminants. This not only ensures a clean working environment but also helps to prevent the growth of bacteria and other microorganisms.

Noise reduction is another consideration when selecting brewery flooring. Breweries can be noisy environments, with machinery, pumps, and ventilation systems creating a significant amount of noise. Choosing a flooring material that absorbs or dampens sound can help create a more comfortable and productive working environment.

Thermal insulation is also an important factor to consider. Breweries often have temperature-controlled areas, such as fermentation rooms and cold storage. The flooring should provide adequate insulation to help maintain the desired temperature and prevent heat loss.

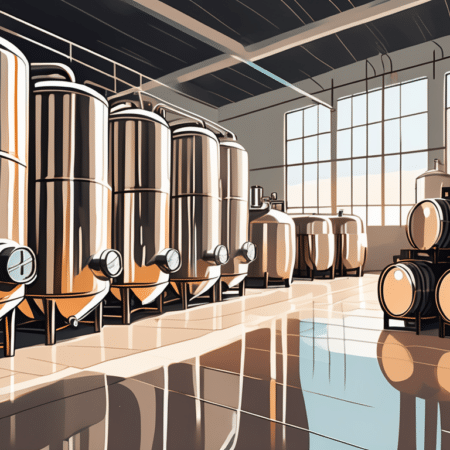

Lastly, it is important to choose a flooring option that aligns with your brewery’s aesthetic appeal and brand image. The flooring can contribute to the overall ambiance and atmosphere of the brewery, enhancing the customer experience and reinforcing your brand identity.

In conclusion, brewery flooring is a critical component of a brewery’s operations. It must be durable, slip-resistant, chemically resistant, easy to clean, and capable of reducing noise and providing thermal insulation. By carefully considering these factors and selecting the right flooring material, breweries can create a safe, hygienic, and visually appealing environment for their employees and customers.

Types of Commercial Flooring for Breweries

When it comes to choosing the right flooring for breweries, there are several options available, each offering distinct benefits and designed to meet specific requirements. Let’s take a closer look at some of the most popular choices:

Epoxy Resin Flooring

Epoxy resin flooring is a top choice for breweries, and for good reason. Its exceptional durability and chemical resistance make it highly suitable for the demanding environment of a brewery. This type of flooring forms a seamless, smooth, and non-porous surface, which not only looks sleek but is also easy to clean and maintain. Additionally, epoxy resin flooring comes in a variety of colors and finishes, allowing you to customize the look of your brewery to match your brand’s aesthetic.

Furthermore, the seamless nature of epoxy resin flooring eliminates the risk of bacteria or mold growth, making it a hygienic option for breweries. This is especially important in areas where food and beverages are being produced, as maintaining a clean and sanitary environment is crucial for product quality.

Polyurethane Concrete Flooring

Another popular choice for brewery flooring is polyurethane concrete flooring. This type of flooring is known for its high performance and durability, making it ideal for areas that experience heavy machinery and equipment use, such as production and packaging areas in breweries.

Polyurethane concrete flooring offers excellent resistance to impact, chemicals, and temperature changes, ensuring that it can withstand the demands of a busy brewery. It also provides a seamless and smooth surface, making it easy to clean and maintain. With its ability to withstand heavy loads and constant foot traffic, polyurethane concrete flooring is a reliable and long-lasting option for breweries.

Rubber Flooring

For areas in breweries where moisture and spills are common, such as cellars and keg rooms, rubber flooring is an excellent choice. Rubber flooring is highly resilient, slip-resistant, and comfortable to walk on, making it a safe and ergonomic option for employees.

One of the key advantages of rubber flooring is its shock-absorbing properties, which help reduce fatigue and provide a cushioned surface for workers who spend long hours on their feet. This can greatly improve employee comfort and productivity. Additionally, rubber flooring is water-resistant and easy to clean, making it a practical choice for areas where spills and moisture are frequent occurrences.

By carefully considering the specific needs and requirements of your brewery, you can choose the most suitable commercial flooring option. Whether you opt for the durability of epoxy resin flooring, the high performance of polyurethane concrete flooring, or the comfort and safety of rubber flooring, investing in quality flooring will contribute to the overall success and efficiency of your brewery.

Evaluating the Pros and Cons of Different Flooring Types

When choosing the right flooring for your brewery, it’s essential to weigh the pros and cons of each option. Let’s take a closer look at the factors to consider:

Durability and Maintenance

Epoxy resin flooring and polyurethane concrete flooring offer excellent durability and require minimal maintenance. They can withstand heavy foot traffic, forklifts, and chemical spills without showing signs of wear and tear. This makes them ideal for a bustling brewery where constant movement and potential accidents are common. The seamless nature of these flooring options also ensures that there are no cracks or crevices where dirt or liquids can accumulate, making cleaning a breeze. On the other hand, rubber flooring, although resilient, may require more regular cleaning and occasional replacement in high-traffic areas due to its softer nature.

Furthermore, epoxy resin flooring and polyurethane concrete flooring are known for their resistance to chemicals and stains. This means that even if a strong cleaning agent or a spillage occurs, the flooring will remain unaffected, maintaining its pristine appearance. Rubber flooring, while generally resistant to stains, may require more effort to remove stubborn marks or spills.

Cost-effectiveness and Longevity

In terms of cost-effectiveness and longevity, epoxy resin flooring and polyurethane concrete flooring are the top contenders. While they may have a higher upfront cost, their longevity and low maintenance requirements make them a cost-effective choice in the long run. These flooring options are designed to withstand the test of time, ensuring that you won’t have to worry about frequent replacements or repairs. This not only saves you money but also reduces the downtime required for flooring maintenance.

On the other hand, rubber flooring, although slightly more affordable, may have a shorter lifespan and higher maintenance costs. Over time, rubber flooring may show signs of wear and tear, especially in areas with heavy foot traffic or where heavy equipment is frequently used. This can result in the need for more frequent replacements, leading to additional expenses.

Safety and Hygiene Factors

All three flooring options provide safety and hygiene benefits, but epoxy resin flooring and polyurethane concrete flooring offer superior resistance to chemicals, stains, and microbial growth. Their seamless and non-porous surfaces prevent contaminants from seeping into the flooring, ensuring a hygienic environment for brewery operations. This is particularly important in a brewery where cleanliness is crucial to maintain the quality of the products being produced.

Epoxy resin flooring and polyurethane concrete flooring also offer excellent slip resistance, reducing the risk of accidents in a fast-paced brewery environment. The textured surface of these flooring options provides traction, even when wet, ensuring that employees can move around safely without the fear of slipping and injuring themselves. Rubber flooring, while also providing slip resistance, may not offer the same level of chemical and stain resistance as epoxy resin and polyurethane concrete flooring.

Additionally, the seamless nature of epoxy resin flooring and polyurethane concrete flooring eliminates any cracks or crevices where bacteria or mold can thrive. This makes cleaning and sanitation procedures more effective, reducing the risk of contamination and ensuring that your brewery meets the highest hygiene standards.

Installation Process for Brewery Flooring

Proper installation is crucial for the longevity and performance of your brewery flooring. Let’s explore the installation process:

Pre-installation Preparations

Prior to installation, the existing flooring must be properly prepared. This involves thorough cleaning, removal of any damaged or uneven surfaces, and ensuring a dry substrate. The flooring contractor will assess the condition of the substrate and make any necessary repairs or adjustments.

Installation Techniques and Timeframes

Depending on the type of flooring chosen, the installation process may vary. Epoxy resin flooring and polyurethane concrete flooring typically involve surface preparation, application of primer, and pouring the resin or concrete mixture. The curing time may vary, usually ranging from 24 to 72 hours. Rubber flooring is typically installed using adhesive or interlocking tiles, which allows for easier and faster installation.

Maintaining Your Brewery Flooring

Proper maintenance practices are essential to prolonging the lifespan and performance of your brewery flooring. Consider the following tips:

Cleaning and Sanitation Practices

Regularly clean your brewery flooring using mild detergents and non-abrasive cleaning tools. Avoid using harsh chemicals that can damage the surface. In areas where spills are common, such as the brewery cellar, promptly clean up any liquid to prevent staining or slipping hazards.

Regular Maintenance Tips

Inspect your flooring regularly for any signs of damage or wear. Address any issues promptly to prevent further deterioration. Depending on the type of flooring, consider applying a protective coating or sealer periodically to maintain its integrity. Follow the manufacturer’s maintenance guidelines for optimal results.

Conclusion

Choosing the right commercial flooring for your brewery is crucial for a safe, efficient, and hygienic work environment. Consider the specific requirements of your operations, the durability and maintenance needs, as well as the safety and hygiene factors. Consult with flooring experts to determine the best option for your brewery, and ensure proper installation and maintenance procedures for long-lasting results. With the right flooring, you can create a brewery that not only produces great beer but also prioritizes the well-being of its employees and customers.