This blog post is sponsored by Slot Drain Systems

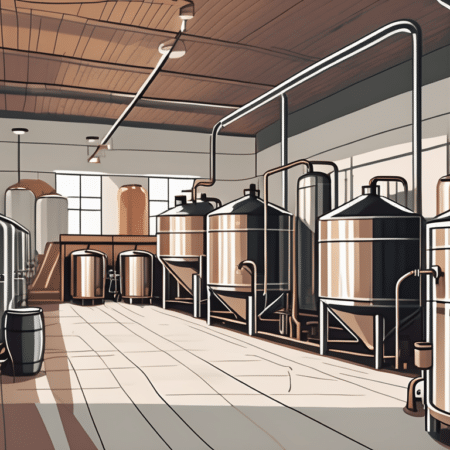

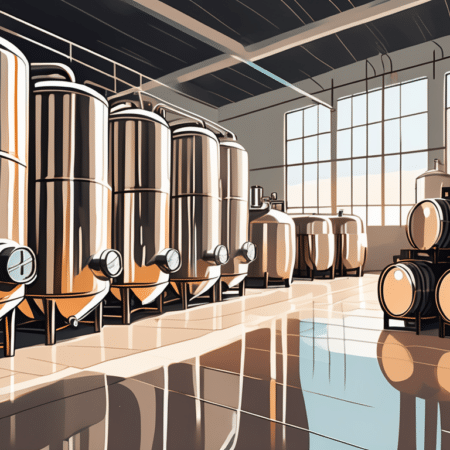

Owning a brewery can be harder than it sounds. There are a million and one things that go into maintaining a successful brewery, and a slip-up in any one category can result in a loss of profits, product contamination, employee injury, and more.

One of the most crucial areas to have squared away is your flooring. Brewery flooring is not your average flooring, it has to be able to take on more abuse than flooring in other types of facilities.

Your brewery floors will see a variety of situations, chemicals, and spills that threaten to damage or destroy it. For this reason, it has to be some really tough stuff. In order to help you keep your brewery flooring in tip-top shape and avoid any mishaps, let’s take a look at 5 tips you can use to do just that.

#1 Use Durable Flooring

Chances are your flooring will end up having heavy kegs, equipment, and machinery testing its strength. In addition to freak accidents, your floor needs to be able to stand up to the regular rigors of everyday use.

The best way to ensure they don’t fail you in these situations is to use a floor coating of some kind. Urethane is one of the most popular options for this because it reinforces a regular concrete floor, which makes it much harder to crack or chip.

#2 Ensure Your Floors Are Slip Resistant

Breweries can be very slippery places without the proper resin in your flooring. Spills and condensation are commonplace, making the need for some kind of anti-slip additive absolutely crucial. Look for something you can add to the resinous flooring in your brewery rather than trying to combat the issue solely with non-slip mats and shoes.

#3 Thermal Shock Resistance Is a Must

A brewery uses liquids that vary from extremely hot to very cold. When these liquids get on the floor, they cause expansion and contraction of the flooring material. This, in turn, causes cracks to develop within the flooring. These cracks can lead to even greater disaster, so it’s important to make sure your brewery flooring can handle a wide degree of temperature fluctuation.

Again, urethane is one of the better options out there for not only reinforcing your floors but providing them with insulation against both hot and cold liquids, which could damage them.

#4 Use The Right Finish

Dangerous chemicals used in the brewery process such as yeast, salt, sugar, acid, malt enzymes, and cleaning agents are known to eat through concrete. Prevent this by covering your floors in some kind of finish that possess chemically-resistant properties. Consider our BREW FLOORS III or BREW FLOORS IV coating systems to protect your brewery floors from harmful chemicals.

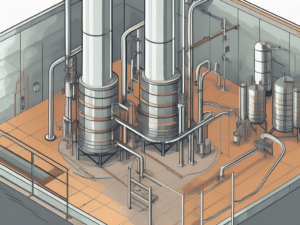

#5 Install A Good Drainage System

Your average drainage system comes complete with large, heavy grates, and hard-to-clean trenches. By installing the right brewery floor drain, such as a slot drainage system, you can ensure proper drainage.

Slot drains are very thin and out of the way, they also feature no grate covers and can be walked on and driven over without issue. They can withstand heavy foot traffic and are built with smoother corners made from stainless steel, lowering the cost of cleaning them by a huge sum compared to normal concrete trench drains.

Putting All The Pieces Together

By making sure you have every tip on this list covered, you can rest easy knowing your brewery flooring has the best protection possible. From chemical resistance to durability, thermal shock resistance, slip resistance, and proper drainage, your floors will be able to stand up to anything, so long as they possess all 5 of these qualities.

2 thoughts on “5 Tips to Avoid Flooring Failure in a Brewery”

Excellent article. No one seems to talk anout floor failure, but it happens. We recommend using coatings on all industrial floors.

This is true. The reality is that floors like anything else are not perfect…but there are steps one can take to increase the life span and help keep it the aesthetic appeal of it.