How Thick is an Epoxy Coating?

Epoxy floor thickness will range from floor to floor. Of course the biggest contributing factor to epoxy thickness is the type of coating you are going to use. Let’s explore the different types of floor coatings and the expected thickness that will result from a properly installed floor.

Epoxy coating thickness is determined by the chemical makeup in which its formulated. When manufacturers are deciding on how thick a coating should be they will alter and adjust chemical makeup to achieve different levels of thickness. Standard epoxy single layer coatings are usually 1-2 mils thick. Depending on who manufactures it and what type of floor the epoxy is being installed on will also play a vital factor in determining final mil thickness. Some projects might call for a thinner coating v. a thick coating.

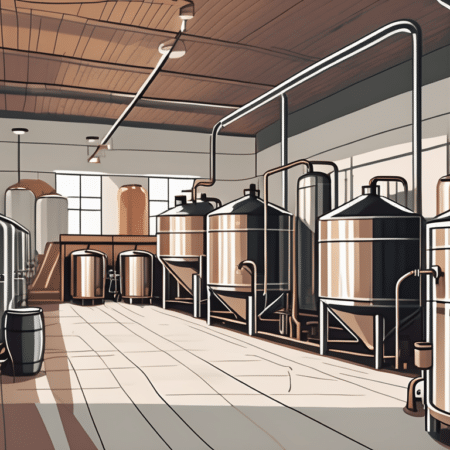

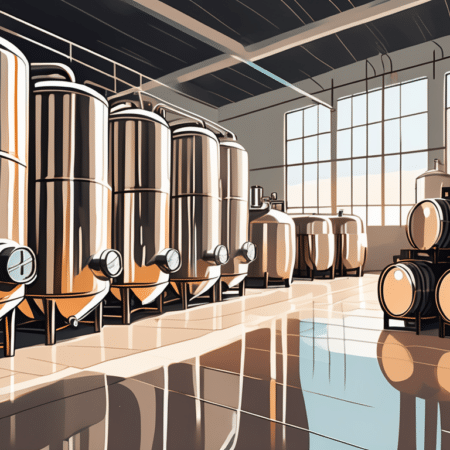

Industrial coatings and all of the products that Brew Floors sells are above industry standard when looking at thickness. Because all of our systems are two and three layered, with the exception of the Brew Floors I mil thickness can be built up with multiple coatings. Epoxies work extremely well as a primer and basecoat for many verticals including industrial, food and beverage, warehouses, garage floors, auto body shops, and many more. Let’s take a look at some of the positives and negatives to using a thin. v. thick epoxy coating.

Polyurethane Coating Thickness Color

Polyurethane coatings make for extremely good coatings for all types of flooring. They are UV resistant, easy to work with and tend to be perform extremely well over long uses of time. Polyurethanes can dry quicker than some fat drying epoxy applications making it a great flooring option for those working under a restricted time window. Polyurethane thickness is similar to that of an epoxy coating and will vary from 2-3 mils when settled and dried.

Novolac

Coating Thickness Color

Novloac floor coatings are specially designed to be able to withstand high levels of acid and chemical resistance. When the epoxy is formulated the per molecule average reactive groups is greater than those of an epoxy giving it high levels of chemical and acid resistance. A single layer novolac coating will dry anywhere from 8-15 mils thick giving the floor extra durability for heavy vehicle traffic and equipment that will be used or stored on the floor.

Check out our best selling two layer novolac floor coating system HERE.

Epoxy Mortar Thickness

Mortar Coatings are the thickest and most durable type of epoxies one could install. Usually comprised of three components these floors are meant to withstand the toughest and harshest environments. They can dry between 125-250 mils thick. Because there is always an aggregate added these floors are not as easily applied and will need use of a trowel to spread the coating evenly. If your floor is badly beaten up and a thin coating will not suffice then an epoxy mortar may be a good option for you. They are extremely chemical/acid resistant and can have a 7,800 psi compressive strength (about twice the strength of concrete!) Yes these floors are no joke. See our Brew Floors IV system if you are interested in learning more. You can find other epoxy products and systems.

Pros v. Cons of Thick v. Thin Coatings

Positives of Using a Thin Epoxy Coating

- Less downtime and quicker drying time

- Work well as primers to be layered upon

- Usually less expensive than thicker coatings

- Can be easier to apply than thicker coatings

Negatives of Using a Think Epoxy Coatin

- Will not standup to wear and tear

- Does not work well covering up imperfections in the floor

- Not as durable and may fail when heavy equipment, vehicles, or other larger items are used on it