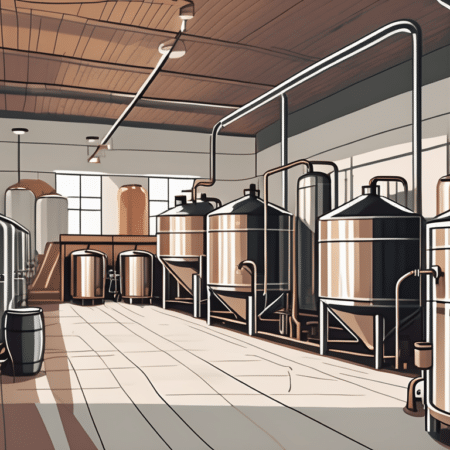

In recent years, the popularity of home brewing has soared. With the rise of craft beer enthusiasts, many aspiring brewers are turning their garages, basements, and spare rooms into their own personal breweries. However, creating the perfect brewing environment is no easy task. One crucial element that often goes overlooked is the flooring. That’s where home brewery epoxy comes in. In this ultimate guide, we will take a comprehensive look at everything you need to know about home brewery epoxy and how it can transform your brewing space.

Understanding the Basics of Home Brewery Epoxy

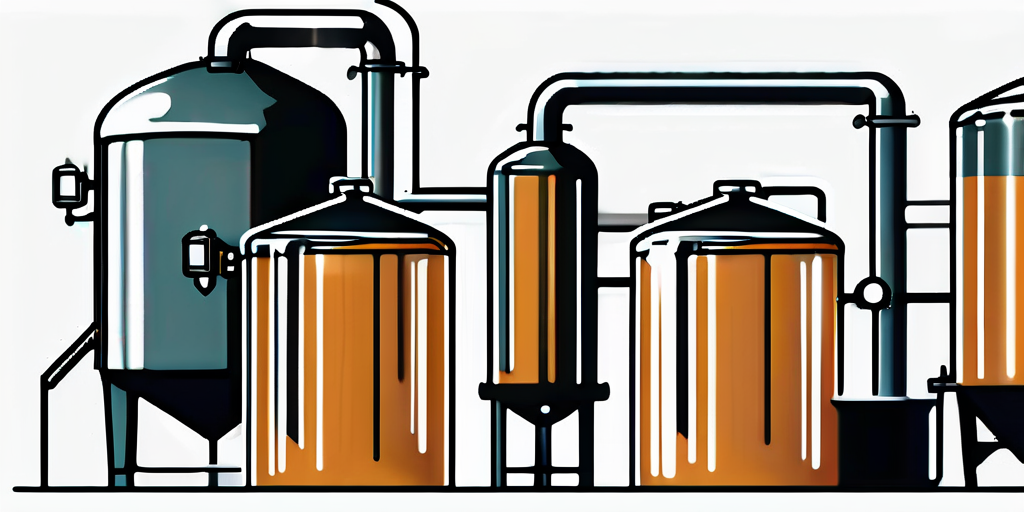

Before diving into the specifics, it’s important to have a clear understanding of what exactly home brewery epoxy is. In simple terms, epoxy is a type of coating that is applied to the flooring of a brewery to create a durable and resistant surface. It is made up of a combination of resins and hardeners, which, when mixed together, create a chemical reaction that forms a strong, protective layer.

Home brewery epoxy offers a range of benefits, making it an ideal choice for any serious brewer. Not only does it provide a smooth and seamless finish, but it also resists stains, chemicals, and temperature fluctuations. Additionally, it offers durability and easy maintenance, ensuring that your brewery floor stays in top condition for years to come.

What is Home Brewery Epoxy?

Home brewery epoxy is specifically formulated for the unique requirements of a brewing environment. While there are various types of epoxy available, it’s essential to choose one that is designed to withstand the harsh conditions of a brewery. Standard epoxy coatings may not be suitable, as they may not offer the necessary resistance to chemicals, hot liquids, and heavy equipment commonly found in a brewing setup.

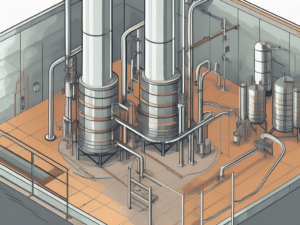

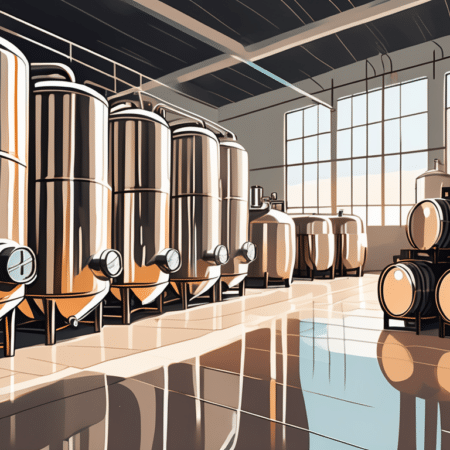

When selecting a home brewery epoxy, it’s important to consider factors such as chemical resistance, impact resistance, and temperature tolerance. The epoxy should be able to withstand exposure to acids, sanitizers, and other brewing chemicals without deteriorating or discoloring. It should also be able to handle the weight and movement of heavy brewing equipment, such as mash tuns and fermentation tanks.

Importance of Epoxy in Home Brewing

- Protection: One of the main reasons why epoxy is essential in home brewing is because it provides unmatched protection to the underlying concrete or substrate. Brewing involves handling corrosive substances like acids and sanitizers, which can damage the flooring over time. Epoxy acts as a barrier, shielding your floor from potential damage.

- Sanitation: Maintaining a clean brewing environment is crucial for producing high-quality beer. Epoxy coatings are resistant to microbial growth, making it easier to maintain a sanitary space. Additionally, epoxy’s seamless finish eliminates the porous spaces where bacteria and contaminants can accumulate, providing a more hygienic brewing environment.

- Safety: A well-designed brewery should prioritize safety. Epoxy coatings can be customized with slip-resistant additives, reducing the risk of accidents caused by wet or slippery floors. This is especially important in areas where spills are common, such as near fermentation tanks or kegging stations.

Furthermore, epoxy coatings can also enhance the overall aesthetics of your home brewery. With a wide range of colors and finishes available, you can create a visually appealing space that reflects your personal style and branding. Whether you prefer a glossy, high-shine look or a more subtle matte finish, there is an epoxy coating option to suit your preferences.

Another advantage of epoxy is its ability to improve the acoustics of your brewery. The smooth and seamless surface helps to reduce noise and echoes, creating a more pleasant and comfortable brewing environment. This can be particularly beneficial if you plan on hosting events or tastings in your home brewery.

Lastly, epoxy coatings are known for their long lifespan. When properly installed and maintained, they can last for many years without the need for frequent repairs or replacements. This not only saves you money in the long run but also ensures that your brewery operations are not disrupted due to flooring issues.

Choosing the Right Epoxy for Your Home Brewery

Now that you understand the importance of epoxy in your home brewery, it’s crucial to choose the right epoxy for your specific needs. Here are some factors to consider when making your selection:

Factors to Consider When Choosing Epoxy:

- Chemical Resistance: Look for epoxy coatings that offer high chemical resistance to withstand the corrosive nature of brewing chemicals.

- Temperature Tolerance: Brewing involves working with various temperatures. Ensure that the epoxy you choose can handle the heat fluctuations without losing its integrity.

- Application Ease: Consider the ease of application and whether it requires professional installation or if it can be applied as a DIY project.

When it comes to setting up your home brewery, the choice of epoxy is not a decision to be taken lightly. The right epoxy coating can make a significant difference in the longevity and functionality of your brewing space. Let’s dive deeper into the factors mentioned above to help you make an informed decision.

Chemical resistance is of utmost importance when it comes to epoxy coatings for your home brewery. Brewing chemicals can be highly corrosive, and without proper protection, your brewing equipment and surfaces can deteriorate rapidly. Look for epoxy coatings that are specifically designed to withstand the harsh chemicals commonly used in brewing, such as cleaning agents and sanitizers. These coatings should provide a barrier against chemical attacks, ensuring the longevity of your brewery setup.

Temperature tolerance is another critical factor to consider. Brewing involves working with different temperatures, from mashing and boiling to fermentation and conditioning. Fluctuations in temperature can cause epoxy coatings to expand and contract, potentially leading to cracks and delamination. Therefore, it is essential to choose an epoxy that can withstand the heat variations commonly encountered in the brewing process. A high-temperature epoxy will ensure the longevity and durability of your brewery surfaces, even under extreme temperature conditions.

Considering the ease of application is also crucial when selecting an epoxy for your home brewery. Depending on your DIY skills and the complexity of your brewing space, you may opt for either a DIY-friendly epoxy or one that requires professional installation. DIY epoxy kits are readily available and typically come with detailed instructions, making them suitable for beginners. However, if you have a larger brewery setup or prefer a more professional finish, hiring an epoxy flooring contractor may be the way to go. They have the expertise and tools to ensure a flawless application, giving you peace of mind and a stunning brewery space.

Different Types of Epoxy for Home Brewing:

There are different types of epoxy coatings available, each catering to specific needs. Some popular options for home brewers include:

- Water-Based Epoxy: Ideal for small home breweries, this type of epoxy is easy to apply and has low VOC emissions. It provides a durable and chemical-resistant finish, making it suitable for most brewing environments.

- Solvent-Based Epoxy: Offering greater durability and chemical resistance, solvent-based epoxy is recommended for larger breweries or those with more demanding operational requirements. It provides a robust protective layer that can withstand heavy foot traffic, equipment movement, and the use of aggressive cleaning agents.

- Novolac Epoxy: This specialized epoxy is designed for extreme conditions and provides exceptional resistance to chemicals and heat. Novolac epoxy is suitable for breweries that handle aggressive substances or operate at higher temperatures. It offers superior protection against chemical attacks and can withstand the harshest brewing environments.

Choosing the right type of epoxy for your home brewery depends on the size of your brewing operation, the specific chemicals used, and the temperature conditions you encounter. Assess your needs and consult with epoxy specialists or fellow brewers to determine the most suitable option for your brewery.