In the brewing industry, one key element that often gets overlooked is the flooring. However, brew flooring plays a crucial role in maintaining a safe and efficient brewing operation. Not only does it need to be able to withstand heavy equipment and constant foot traffic, but it should also be resistant to chemicals, moisture, and temperature fluctuations. In this ultimate guide, we will explore the importance of brew flooring, the different types available, the pros and cons of each option, essential tips for choosing the right flooring, and the installation process.

Understanding the Importance of Brew Flooring

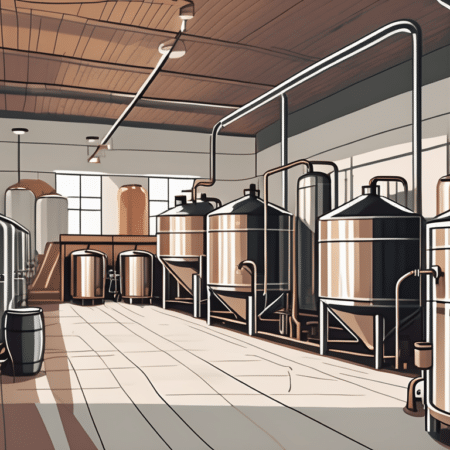

The flooring in a brewery serves a vital purpose beyond just aesthetics. It is a critical component that affects the overall safety, cleanliness, and longevity of the brewing operation. By investing in the right type of brew flooring, brewers can ensure a more efficient workflow, improve employee safety, and maintain the quality of their products.

The Role of Flooring in a Brewery

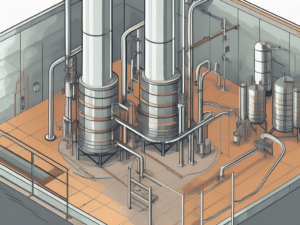

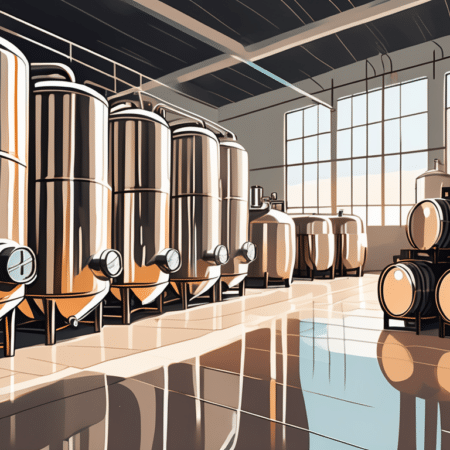

The flooring in a brewery not only needs to be able to withstand heavy loads from equipment such as fermenters, mash tuns, and kegs but also provide a comfortable working surface for the brewers and staff. It should be slip-resistant, providing traction even in wet or potentially hazardous conditions. Additionally, it should be impervious to liquids to prevent any seepage into the subfloor, which could lead to mold growth or structural damage.

Furthermore, the flooring should be designed to handle the unique challenges of a brewery environment. Breweries are known for their high humidity levels due to the fermentation process, which can lead to condensation and moisture buildup. Therefore, the flooring should have moisture-resistant properties to prevent any water damage or the growth of bacteria and fungi.

Another important aspect to consider is the impact of heavy equipment on the flooring. Breweries house large tanks, kegs, and other machinery that can exert significant weight on the floor. Therefore, the flooring material should have excellent load-bearing capabilities to withstand these heavy loads without cracking or deteriorating over time.

Key Factors to Consider in Brew Flooring

When selecting brew flooring, there are several factors to consider. Firstly, the flooring material should be resistant to the chemicals commonly used in the brewing process, such as acids, cleaning agents, and sanitizers. These substances can be highly corrosive and can cause damage to the floor if it is not chemically resistant.

Secondly, it should be able to withstand temperature fluctuations, as the brewing process often involves hot or cold liquids. The flooring should not expand or contract excessively with temperature changes to avoid any structural issues or gaps that could harbor bacteria or compromise the integrity of the floor.

Lastly, it should be durable and easy to clean, as breweries require regular cleaning and maintenance to ensure hygiene standards are met. The flooring should be resistant to staining and should not absorb any liquids, making it easier to clean spills and maintain a sanitary environment.

Additionally, the flooring should be aesthetically pleasing and contribute to the overall ambiance of the brewery. It can be customized with different colors, patterns, or textures to create a unique and inviting atmosphere for visitors.

In conclusion, brew flooring plays a crucial role in the success of a brewery. It not only provides a safe and functional working surface but also contributes to the overall cleanliness, efficiency, and longevity of the brewing operation. By carefully considering the factors mentioned above, brewers can select the right type of flooring that meets their specific needs and ensures the production of high-quality brews.

Different Types of Brew Flooring

When it comes to breweries, the choice of flooring is crucial. The right flooring material can enhance the functionality and efficiency of the brewing process, while also ensuring a safe and hygienic environment. Let’s explore some of the different types of flooring options available for breweries and discover their unique characteristics and benefits.

Epoxy Resin Flooring

Epoxy resin flooring is a popular choice in breweries, and for good reason. This type of flooring offers excellent resistance to chemicals, making it ideal for environments where spills and splashes are common. Its durability is also a standout feature, as it can withstand heavy foot traffic and the movement of equipment without showing signs of wear and tear.

One of the key advantages of epoxy resin flooring is its seamless finish. Unlike other flooring materials, epoxy can be applied in a way that eliminates joints and seams, creating a smooth and hygienic surface. This makes it easier to clean and maintain, a crucial factor in breweries where regular sanitization is necessary to ensure the quality and safety of the beer being produced.

Another benefit of epoxy flooring is its versatility. It can be customized with various colors and textures, allowing brewers to create a unique and visually appealing space that reflects their brand identity. Whether it’s a vibrant and eye-catching floor or a more understated and professional look, epoxy resin flooring can deliver.

Polyurethane Flooring

For breweries that require a flooring material with exceptional resistance to impact, abrasion, and chemicals, polyurethane flooring is an excellent choice. This type of flooring is known for its durability and ability to withstand heavy use and abuse.

One of the standout features of polyurethane flooring is its slip resistance. The surface of this flooring material is designed to provide traction, reducing the risk of slips and falls in a brewery environment where spills and wet conditions are common. This makes it a safe option for both brewery workers and visitors.

In addition to its durability and slip resistance, polyurethane flooring also offers good thermal properties. Breweries often experience temperature fluctuations due to the brewing process, and polyurethane flooring can handle these changes without warping or deteriorating. This ensures that the flooring remains in optimal condition, even in challenging environmental conditions.

Rubber and Vinyl Flooring

When it comes to comfort and slip resistance, rubber and vinyl flooring are popular choices for breweries. These materials provide a cushioned and forgiving surface underfoot, reducing fatigue for workers who spend long hours on their feet.

Rubber flooring, in particular, is known for its high resistance to impact and abrasion. It can withstand heavy equipment and the constant movement of kegs and barrels without showing signs of wear. This makes it a durable option for breweries that experience a high level of activity.

On the other hand, vinyl flooring offers a cost-effective solution with good durability and ease of installation. It is a versatile material that can mimic the appearance of other flooring types, such as wood or stone, allowing breweries to achieve a desired aesthetic without breaking the bank.

Both rubber and vinyl flooring are easy to clean and maintain, making them suitable choices for breweries that prioritize hygiene and cleanliness.

Choosing the right flooring for a brewery is a decision that should not be taken lightly. Each type of flooring material offers its own set of advantages, and it’s important to consider factors such as durability, resistance to chemicals, slip resistance, and ease of maintenance. By selecting the right flooring, breweries can create a safe, efficient, and visually appealing space that enhances the brewing process and ensures the production of high-quality beer.

Pros and Cons of Various Brew Flooring

Evaluating the Benefits of Each Flooring Type

Each type of brew flooring has its own advantages and benefits. Epoxy resin flooring, for example, offers superior chemical resistance and a seamless finish, making it easy to clean and maintain. Polyurethane flooring, on the other hand, excels in impact and abrasion resistance, making it ideal for heavy equipment and high foot traffic areas. Rubber and vinyl flooring provide excellent slip resistance and comfort for the brewery staff.

Potential Drawbacks to Consider

While each type of brew flooring has its benefits, it’s important to consider any potential drawbacks as well. Epoxy resin flooring, for example, may require professional installation and can have a higher initial cost. Polyurethane flooring, although durable, may not provide the same level of customization as epoxy resin flooring. Rubber and vinyl flooring, while comfortable and cost-effective, may not offer the same level of durability in high traffic areas.

Essential Tips for Choosing the Right Brew Flooring

Assessing Your Brewery’s Needs

Before making a decision on which brew flooring to install, it’s important to assess your brewery’s specific needs. Consider factors like the type of brewing operations, the level of foot traffic, the presence of heavy equipment and machinery, and the desired aesthetic appeal. By understanding your brewery’s unique requirements, you can make a more informed decision on the best flooring material to choose.

Budget Considerations for Brew Flooring

While cost should not be the sole determining factor when choosing brew flooring, it is an important consideration. Take into account the upfront installation costs, as well as any long-term maintenance and repair expenses. Remember that investing in high-quality flooring upfront can save you money in the long run by avoiding frequent repairs and replacements.

Longevity and Maintenance Aspects

Consider the expected lifespan of the flooring material and the level of maintenance required to keep it in optimal condition. Some materials may require more frequent cleaning or periodic resealing, while others may be more resistant to wear and tear. Evaluate the long-term costs and effort associated with maintaining each flooring option.

Installation Process for Brew Flooring

Preparing Your Brewery for New Flooring

Prior to installing new brew flooring, proper preparation is crucial. Remove any existing flooring materials and thoroughly clean the substrate. Repair any cracks or uneven surfaces to ensure a smooth and level base for the new flooring. Adequate preparation will help prevent any issues or compromised durability of the new floor.

Step-by-Step Guide to Flooring Installation

The exact installation process will vary depending on the chosen flooring material, but generally, it involves applying a primer, followed by a base coat and topcoat. This ensures a strong bond and provides the desired finish and durability. It is important to follow the manufacturer’s instructions and seek professional assistance if needed.

By understanding the importance of brew flooring, exploring the different types available, considering the pros and cons, and following essential tips for selection and installation, brewers can make an informed decision that meets the unique needs of their brewery. Remember, the right brew flooring is a long-term investment that enhances safety, efficiency, and the overall brewing experience.