In the world of craft beer, every detail matters. From the recipe to the brewing process, every step is meticulously planned to create the perfect pint. One often overlooked aspect of a brewery is the design of the brew floor. In this ultimate guide, we will explore the tips and tricks to help you design a brew floor that meets your brewery’s needs and sets your operation up for success.

Understanding the Basics of a Brew Floor

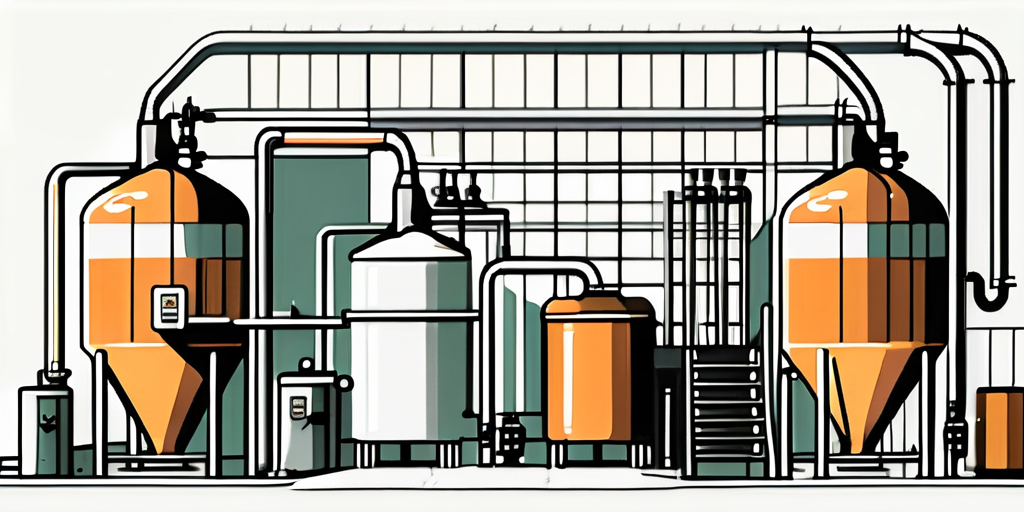

Before diving into the design process, it’s important to understand the basics of a brew floor. The brew floor is the foundation of your brewery, where all the magic happens. It needs to be functional, durable, and safe for both your staff and your equipment.

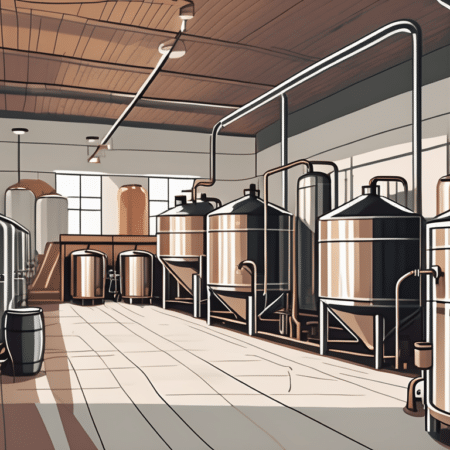

The brew floor is not just a simple concrete slab. It is a carefully planned and designed space that takes into consideration various factors to ensure optimal brewing conditions. From layout to equipment placement, every aspect of the brew floor contributes to the success of your brewery.

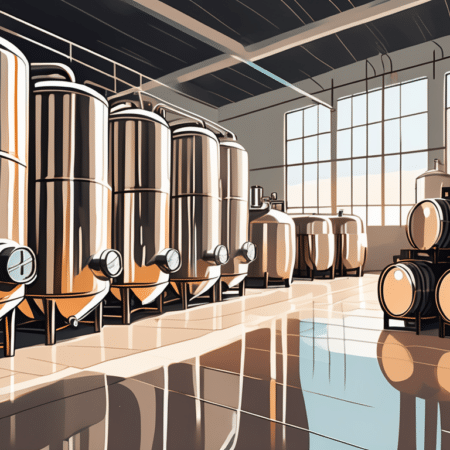

When it comes to the design of your brew floor, there are several key considerations to keep in mind. One of the most important factors is the layout. The layout of your brew floor should be carefully planned to maximize efficiency and productivity. This involves strategically placing different brewing stations, storage areas, and utilities to create a seamless workflow.

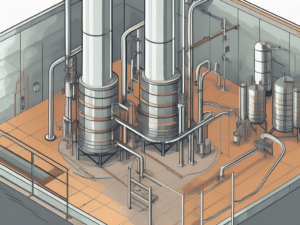

Space utilization is another crucial aspect of brew floor design. Every inch of the floor should be utilized effectively to ensure that you have enough room for all the necessary equipment and processes. This includes considering the height of the ceiling to accommodate tall fermentation tanks and the placement of utilities such as water, gas, and electrical lines.

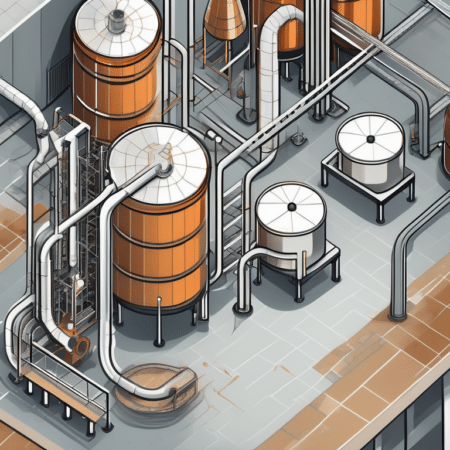

Equipment placement is yet another critical component of a well-designed brew floor. Each piece of brewing equipment, from mash tuns to fermenters, needs to be positioned in a way that allows for easy access and efficient operation. This includes considering the flow of ingredients and the movement of staff members during the brewing process.

Lastly, the choice of flooring materials is essential for a brew floor. The flooring needs to be able to withstand the heavy equipment, constant moisture, and chemicals commonly found in a brewery. Common options for brew floor materials include epoxy coatings, concrete sealers, and specialized brewery flooring systems.

Overall, the design of your brew floor is not something to be taken lightly. It requires careful planning, attention to detail, and a deep understanding of the brewing process. By considering the layout, space utilization, equipment placement, and flooring materials, you can create a brew floor that is not only functional and efficient but also safe for your staff and equipment.

Planning Your Brew Floor Design

Now that you understand the basics, it’s time to dive into the planning process. When designing your brew floor, there are a few key considerations to keep in mind.

Space Considerations

One of the first things to consider when planning your brew floor design is the available space. Take accurate measurements and assess how much space you have to work with. Consider factors such as ceiling height, doorways, and any potential obstacles that may impact the layout.

Having ample space is crucial for a successful brewing operation. It allows for easy movement and access to equipment, ensuring a smooth workflow. Additionally, sufficient space allows for future expansion and growth of your brewery.

When considering the layout, think about the flow of materials and personnel. A well-designed brew floor should have designated areas for each step of the brewing process, from milling the grains to packaging the final product. By carefully planning the placement of each area, you can optimize efficiency and minimize the risk of cross-contamination.

Equipment Placement

The placement of your equipment is critical for ensuring a smooth brewing process. Consider the workflow and arrange your equipment in a logical sequence. This will help minimize unnecessary movement and improve efficiency.

When deciding on the placement of your equipment, take into account the specific requirements of each piece. Some equipment may require additional space for maintenance or ventilation. It’s also important to consider the accessibility of equipment for cleaning and maintenance purposes.

Another factor to consider is the proximity of utilities such as water, electricity, and gas. Ensuring easy access to these utilities will simplify the installation and maintenance of your equipment.

Furthermore, consider the future growth and expansion of your brewery. Leave enough space for additional equipment or upgrades that you may require as your business expands.

By carefully planning the placement of your equipment, you can create a brew floor that maximizes efficiency, minimizes downtime, and enhances the overall brewing experience.

Material Selection for Your Brew Floor

Once you have a solid plan in place, it’s time to consider the materials for your brew floor. The right flooring material can make a significant difference in the overall functionality and longevity of your brew floor.

When it comes to selecting the perfect material for your brew floor, there are several factors to consider. Not only do you want a material that is aesthetically pleasing, but you also need one that can withstand the unique demands of a brewery environment.

Evaluating Different Flooring Materials

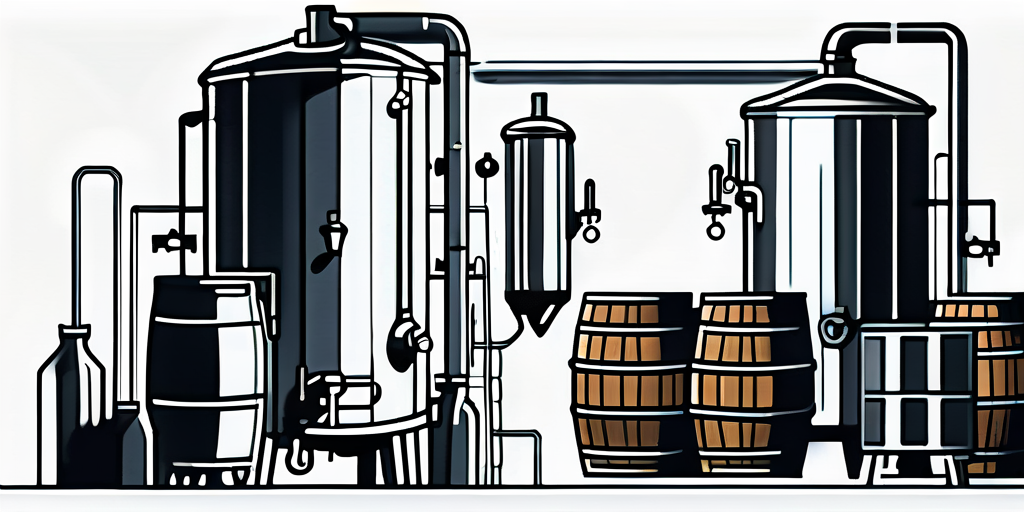

There is a wide range of flooring materials available for brew floors, each with its own set of pros and cons. Some common options include epoxy, concrete, and rubber. Let’s take a closer look at each of these materials and what they have to offer.

Epoxy: Epoxy flooring is a popular choice for breweries due to its durability and chemical resistance. It creates a seamless, non-porous surface that is easy to clean and maintain. Epoxy is also available in a variety of colors and finishes, allowing you to customize the look of your brew floor.

Concrete: Concrete is a classic choice for brew floors, known for its strength and durability. It can withstand heavy foot traffic and is resistant to spills and stains. However, concrete may require regular sealing to prevent moisture absorption and potential damage.

Rubber: Rubber flooring offers excellent slip resistance and cushioning, making it a safe and comfortable option for brewery floors. It is also resistant to chemicals and can withstand the impact of heavy equipment. However, rubber flooring may not be as visually appealing as other options.

Consider factors such as durability, ease of maintenance, and resistance to heat and chemicals when evaluating different flooring materials for your brew floor. Each material has its own unique properties, so it’s important to choose one that aligns with your specific needs and preferences.

Durability and Maintenance Factors

In a brewery setting, durability and maintenance are key considerations. Your brew floor will be subjected to heavy foot traffic, spills, and potential chemical exposure. It’s essential to select a material that can withstand these challenges and is easy to clean and maintain.

Durability: Look for a flooring material that is known for its durability and can handle the demands of a brewery environment. This includes resistance to impact, abrasion, and wear. A durable floor will ensure that your brewery can operate smoothly without the worry of constant repairs or replacements.

Maintenance: Keeping your brew floor clean and well-maintained is crucial for maintaining a hygienic and safe brewing environment. Choose a material that is easy to clean and resistant to stains. It’s also important to consider any specific maintenance requirements, such as regular sealing or special cleaning products.

By carefully evaluating different flooring materials and considering factors such as durability and maintenance, you can select the ideal material for your brew floor. Remember, the right choice will not only enhance the functionality of your brewery but also contribute to its longevity and success.

Safety Considerations in Brew Floor Design

Safety should be a top priority in any brewery. When designing your brew floor, there are several safety considerations to keep in mind.

Slip-Resistance and Drainage

Brew floors can be wet and slippery, posing a risk to your staff. Opt for flooring materials that offer slip-resistance and proper drainage to minimize the risk of accidents. Textured surfaces and strategically placed floor drains can greatly enhance safety.

Chemical and Heat Resistance

Breweries handle various chemicals and work with hot liquids. Choose flooring materials that are resistant to chemicals commonly used in brewing and can withstand high temperatures without deteriorating or becoming slippery.

Aesthetics and Functionality in Brew Floor Design

While functionality is paramount, aesthetics also play a role in your brew floor design. A visually appealing brew floor can enhance the overall ambiance of your brewery and even serve as a branding opportunity.

Balancing Visual Appeal with Practicality

When selecting flooring materials and designing the layout, strike a balance between visual appeal and practicality. Consider your brewery’s branding and design elements that can be incorporated into the brew floor to create a cohesive look.

Incorporating Branding into Your Brew Floor Design

Your brew floor can be an opportunity to showcase your brewery’s brand. Consider using colored epoxy or customized flooring patterns to incorporate your logo or other brand elements into the design. This can create a unique and memorable experience for visitors.

In conclusion, designing a brew floor requires careful planning and consideration of various factors. From understanding the basics and planning the layout to selecting the right materials and ensuring safety, each step is crucial in creating a functional and visually appealing brew floor. By following the tips and tricks outlined in this guide, you can design a brew floor that enhances your brewing process, prioritizes safety, and reflects your brewery’s unique identity.